In the steel industry, the dry quenching system is a crucial part of the production process. However, the thermal shock failure of refractory bricks in this system often brings about significant economic and operational challenges. Statistics show that steel plants may face losses of up to $500,000 annually due to non - planned shutdowns caused by refractory brick failures, not to mention the impact on production schedules.

The ratio of mullite to corundum in high - alumina mullite refractory bricks is a key factor affecting their thermal shock resistance. When the mullite content is around 60% - 70% and the corundum content is 30% - 40%, the refractory bricks can achieve better thermal shock resistance. This is because mullite has good thermal stability and low thermal expansion coefficient, while corundum provides high strength. A proper ratio can balance the two properties, improving the overall performance of the refractory bricks.

The pore distribution and grain boundary bonding strength in the microstructure of refractory bricks play an important role in enhancing their thermal shock resistance. A uniform pore distribution can absorb and dissipate thermal stress. For example, when the average pore size is controlled between 0.1 - 1 mm and the porosity is about 15% - 20%, the refractory bricks can better withstand thermal shock. In addition, strong grain boundary bonding can prevent crack propagation, further improving the heat - shock resistance of the bricks.

The temperature gradient and holding time during the sintering process are critical for controlling the stability of refractory materials. A proper temperature gradient can ensure the uniform densification of the material. For instance, a slow heating rate of 5 - 10°C per minute in the initial stage and a rapid heating rate of 20 - 30°C per minute in the later stage can optimize the internal structure of the refractory bricks. The holding time also affects the crystallization and bonding of the material. A holding time of 2 - 3 hours at the maximum sintering temperature can improve the thermal shock resistance of the bricks.

The thermal cycle frequency and temperature change in the service environment have a real - world impact on the performance of refractory bricks. In a dry quenching system, if the thermal cycle frequency is high (e.g., more than 10 cycles per day) and the temperature change range is large (e.g., from 200°C to 1000°C), the thermal shock resistance of the refractory bricks will be severely tested. Therefore, when selecting refractory bricks, the specific service environment parameters need to be fully considered.

Let's take two steel plants as an example. Plant A uses high - alumina mullite refractory bricks with a mullite - corundum ratio of 65:35, a well - designed microstructure, and a proper sintering process. Plant B uses bricks with a less - optimized ratio and process. After one year of operation, the refractory bricks in Plant A have a service life that is 30% longer than those in Plant B, and the non - planned shutdown times are reduced by 40%.

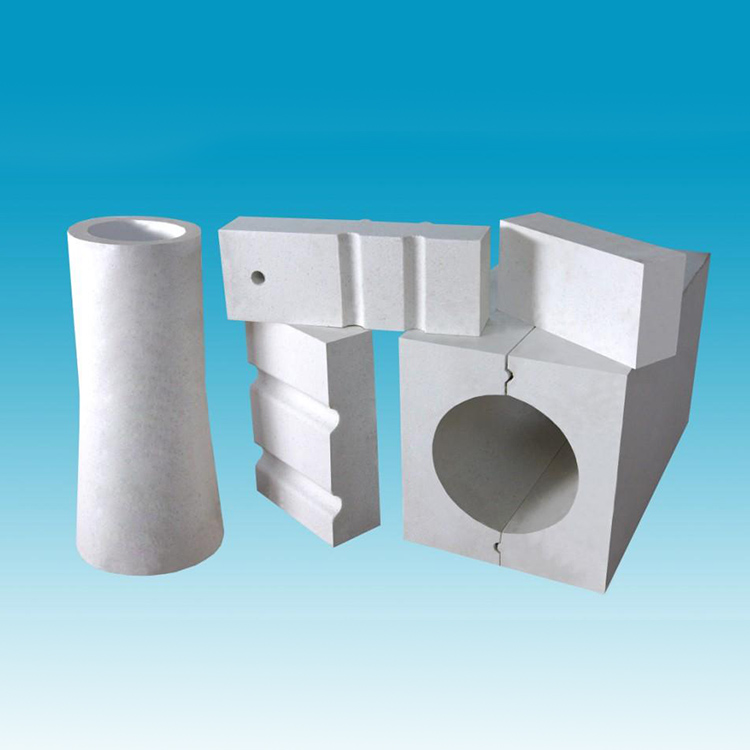

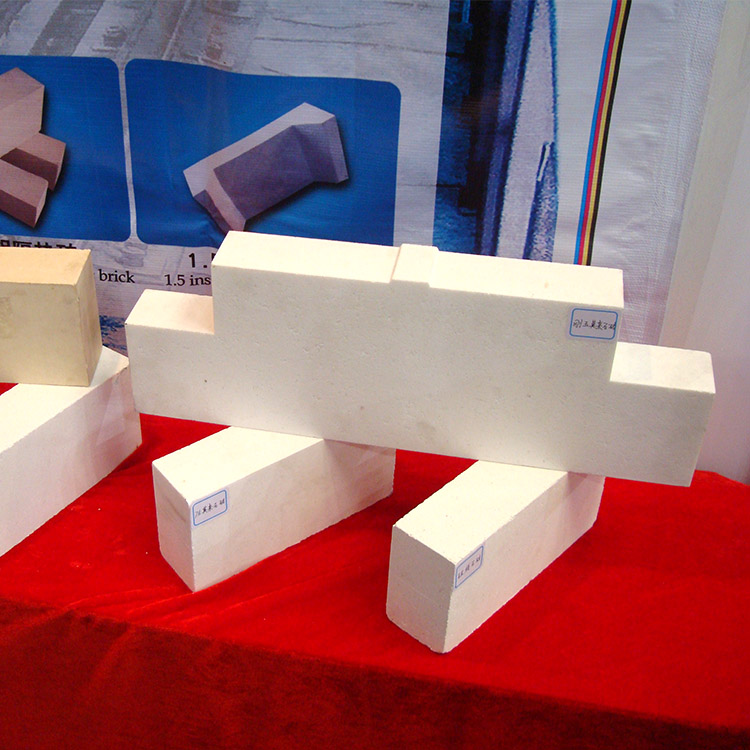

To improve the thermal shock resistance of high - alumina mullite refractory bricks in the dry quenching system, a comprehensive optimization from material selection, manufacturing to installation is required. In terms of material selection, choose the appropriate mullite - corundum ratio according to the service environment. In the manufacturing process, strictly control the microstructure design and sintering process. During installation, ensure the correct installation method to avoid stress concentration. By using our high - quality high - alumina mullite refractory bricks, you can effectively extend the kiln life, reduce non - planned shutdown risks, and achieve efficient and long - term stable operation of refractory materials.

Discover Our High - Alumina Mullite Refractory Bricks Now!

Do you have any questions about the thermal shock resistance of refractory bricks in the dry quenching system? Share your thoughts and experiences with us!