In the steel industry, refractory bricks play a crucial role in the lining of high - temperature furnaces. However, they are constantly exposed to extreme temperature variations, which pose significant challenges to their performance and durability.

During the steel - making process, furnaces experience rapid temperature changes. For example, in a typical steel - making cycle, the temperature in a converter can rise from room temperature to over 1600°C and then drop rapidly. Traditional high - alumina bricks often struggle in such conditions. Their poor thermal shock resistance can lead to a 30% - 50% reduction in the lining life of the furnace, increasing the risk of furnace shutdowns by up to 20%.

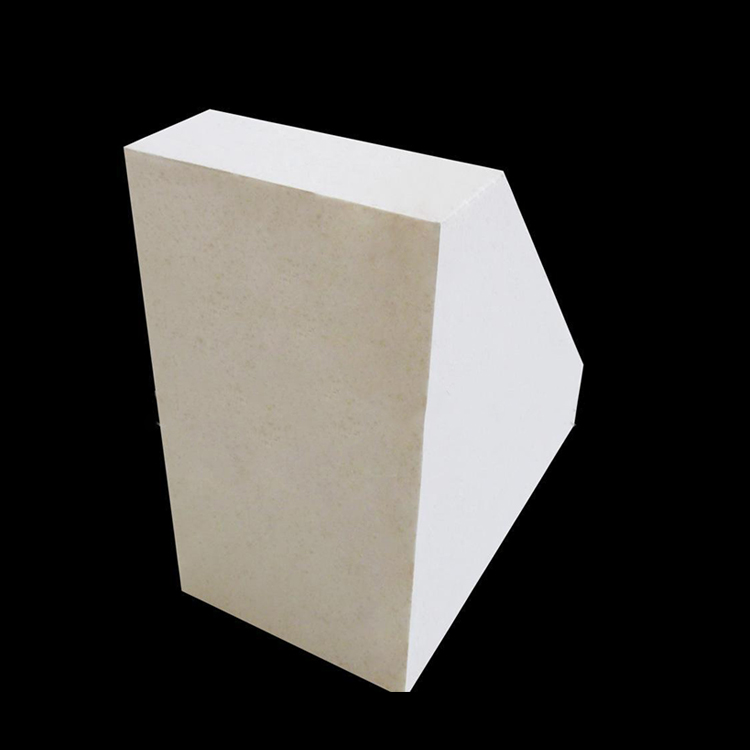

Andalusite refractory bricks offer several significant advantages over high - alumina bricks. In terms of thermal stability, andalusite bricks can maintain their structural integrity at high temperatures. Their thermal expansion coefficient is about 20% lower than that of high - alumina bricks, which means they are less likely to crack during temperature changes. In addition, andalusite bricks have better creep resistance. Under a constant load at high temperatures, the creep rate of andalusite bricks is approximately 30% lower than that of high - alumina bricks, ensuring the long - term stability of the furnace lining.

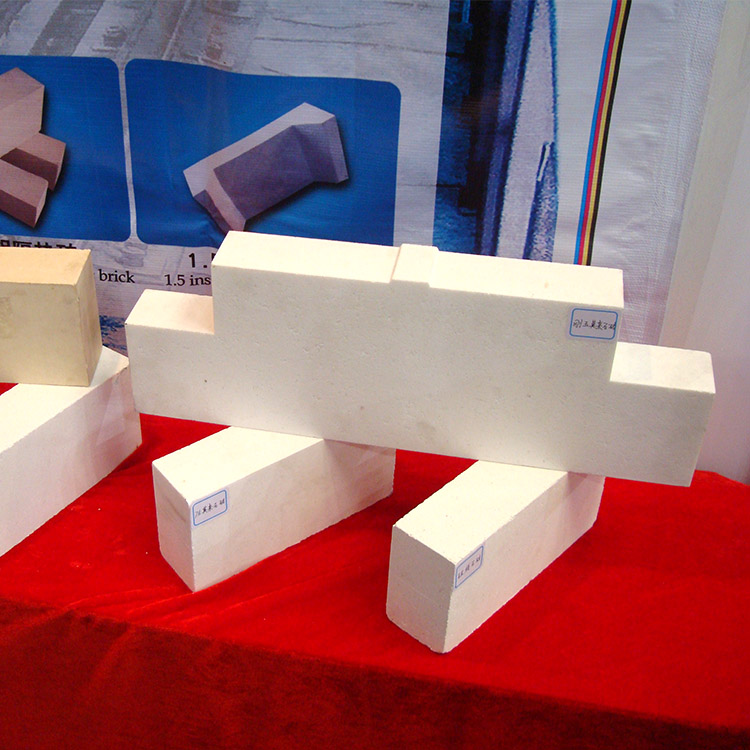

The four key performance indicators of andalusite refractory bricks are cold crushing strength, refractoriness under load, creep resistance, and thermal shock resistance. Cold crushing strength measures the ability of the brick to withstand pressure at room temperature. A well - made andalusite brick typically has a cold crushing strength of 80 - 120 MPa. The refractoriness under load is the temperature at which the brick begins to deform under a specified load. For andalusite bricks, this temperature can reach 1600 - 1700°C. Creep resistance refers to the ability of the brick to resist deformation under long - term high - temperature and load conditions. Thermal shock resistance is tested by subjecting the brick to rapid heating and cooling cycles. Andalusite bricks can usually withstand more than 30 thermal shock cycles without significant damage.

In converter and electric furnace scenarios, these performance indicators have a direct impact on the furnace lining life. In a converter, the high thermal shock resistance of andalusite bricks can extend the lining life by up to 50% compared to high - alumina bricks. In an electric furnace, the excellent creep resistance ensures that the furnace lining remains stable during long - term operation, reducing the frequency of repairs and replacements.

The comprehensive performance of andalusite refractory bricks can be improved through optimized manufacturing processes. By adjusting the raw material ratio, such as increasing the proportion of andalusite raw materials, the thermal shock resistance and other properties can be enhanced. The firing system also plays a crucial role. A well - controlled firing temperature and time can improve the density and strength of the bricks. For example, by using a slow - heating and long - holding firing system, the internal structure of the bricks becomes more uniform, resulting in better overall performance.

Several steel mills have adopted andalusite refractory bricks and achieved remarkable results. One anonymous steel mill reported that after replacing high - alumina bricks with andalusite bricks in their converters, the furnace lining life increased from 1500 heats to 2200 heats, a significant improvement of about 47%. Another steel mill using andalusite bricks in electric furnaces reduced their maintenance costs by 30% due to the longer - lasting furnace lining.

"Andalusite refractory bricks are a game - changer in the steel industry. Their excellent performance under extreme temperature conditions can significantly improve the efficiency and safety of steel production." - Industry Expert

Selecting the right refractory bricks can bring substantial benefits to steel enterprises. By using andalusite refractory bricks, steel mills can reduce operating costs through longer furnace lining life, less frequent repairs, and lower energy consumption. Moreover, it enhances safety by reducing the risk of furnace breakdowns. To learn more about the thermal shock resistance testing standards and other technical details of andalusite refractory bricks, click here.