In the dry quenching system of steel plants, refractory bricks often face challenges such as spalling and cracking due to frequent thermal shock impacts. These issues lead to unplanned furnace shutdowns and high maintenance costs. This article delves into a typical case of thermal shock damage to refractory bricks in the dry quenching system and presents protective strategies.

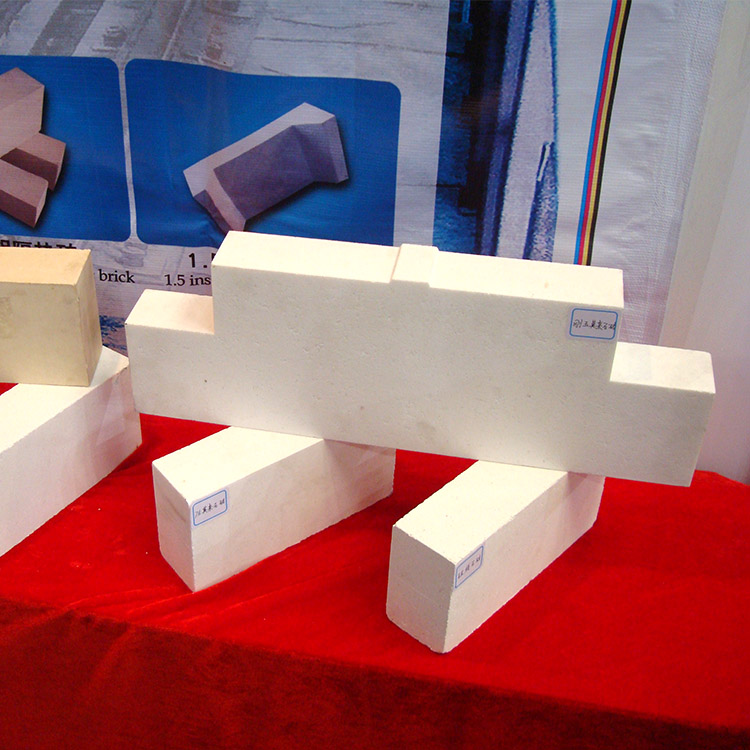

Let's start with a real - world example. In a certain steel plant, the dry quenching system's refractory bricks started to show signs of failure after a period of operation. The high - alumina mullite refractory bricks, which are commonly used in such systems, experienced significant spalling and cracking. The plant had to shut down the furnace unplanned, incurring a large amount of maintenance costs and production losses.

To understand the causes of this thermal shock failure, we need to analyze several key factors that affect the thermal shock resistance of high - alumina mullite refractory bricks. First, the raw material ratio plays a crucial role. Different raw material proportions can lead to different physical and chemical properties of the refractory bricks. For example, a higher proportion of certain raw materials may enhance the strength but reduce the thermal shock resistance. Through actual measurements and field observations, we found that in some cases, a raw material ratio with a higher content of alumina in the high - alumina mullite refractory bricks showed better performance under extreme thermal shock conditions.

The microstructure of the refractory bricks is another important factor. A well - designed microstructure can effectively improve the thermal shock resistance. For instance, a microstructure with appropriate porosity can absorb the stress caused by thermal shock. By comparing different products, we found that those with a more uniform and optimized pore distribution had better thermal shock resistance. In a test, the refractory bricks with a well - controlled pore structure could withstand up to 150 thermal shock cycles, while others with a less - optimized structure only endured about 80 cycles before significant damage occurred.

The sintering process control also has a significant impact on the thermal shock performance. An improper sintering process can lead to uneven internal structure and reduced thermal shock resistance. For example, if the sintering temperature is too high or the sintering time is too long, the refractory bricks may become overly dense, which is not conducive to stress release during thermal shock. On the other hand, if the sintering is insufficient, the strength of the bricks will be compromised.

The service environment, especially the thermal cycle frequency, is also a critical factor. In the dry quenching system, the refractory bricks are exposed to frequent and rapid temperature changes. The higher the thermal cycle frequency, the greater the stress on the refractory bricks. In some high - intensity production environments, the thermal cycle frequency can reach several times per day, which poses a great challenge to the thermal shock resistance of the refractory bricks.

Based on the above analysis, we can provide a series of optimization suggestions for the whole process of material selection, manufacturing, and installation. When selecting materials, metallurgical engineers should consider the specific service environment and requirements. For example, in high - thermal - shock - frequency environments, refractory bricks with better thermal shock resistance should be selected. During the manufacturing process, strict control of raw material ratio, microstructure design, and sintering process is necessary. In the installation process, proper installation methods should be adopted to ensure the stability of the refractory bricks.

Do you have any experiences or questions about the thermal shock failure of refractory bricks in the dry quenching system? Feel free to leave a message and share your thoughts.