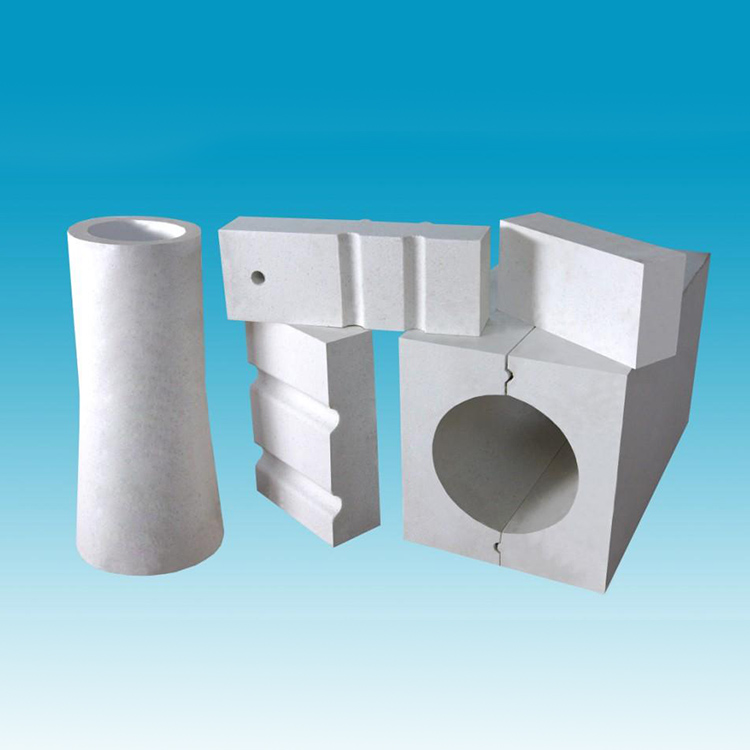

In the steel industry, the dry quenching system is a crucial part of the steel - making process. High - alumina mullite refractory bricks play a vital role in the dry quenching system, but their thermal shock resistance often determines the efficiency and stability of the entire system. This article delves into the key factors affecting the thermal shock resistance of these refractory bricks from multiple aspects.

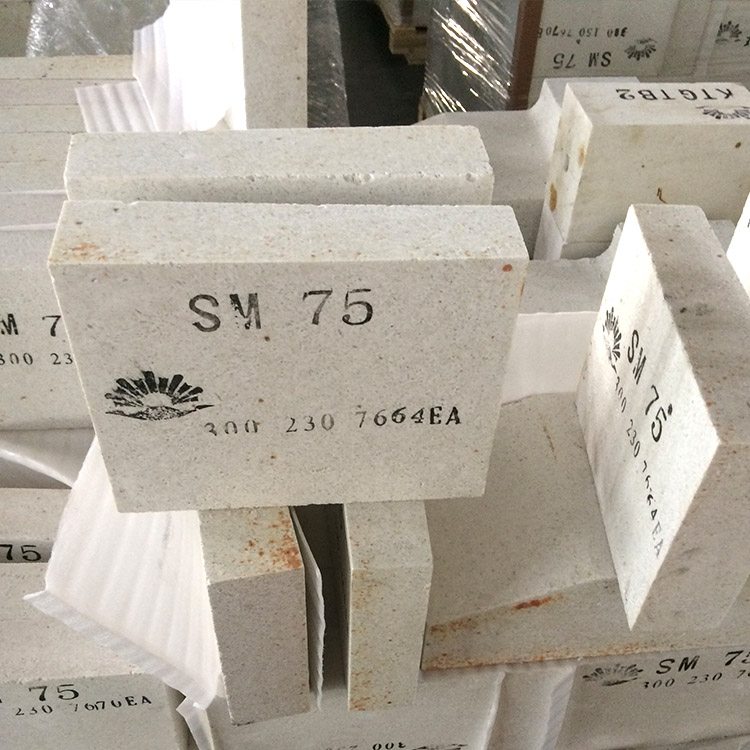

The ratio of mullite to corundum in the raw material mixture is of great significance. For example, in a certain steel plant, when the ratio of mullite to corundum was 3:2, the refractory bricks showed relatively good thermal shock resistance. Laboratory tests indicated that after 50 thermal shock cycles, the damage area of the refractory bricks was only about 15%. However, when the ratio was adjusted to 1:4, the damage area increased to about 30% after the same number of thermal shock cycles. This shows that an appropriate ratio of mullite to corundum can effectively improve the thermal shock resistance of refractory bricks.

The pore distribution and grain boundary bonding strength in the microstructure design are key factors affecting the performance of refractory bricks. A well - designed pore distribution can effectively buffer thermal stress. For instance, in some cases, a uniform pore distribution with an average pore size of about 0.5 - 1mm can enhance the thermal shock resistance of the material. At the same time, a strong grain boundary bonding strength can prevent crack propagation during thermal shock. According to expert opinions, improving the grain boundary bonding strength through appropriate additives can reduce the crack growth rate by about 20 - 30%.

In the sintering process, temperature control and holding time are crucial for optimizing the physical properties of refractory bricks. In a real - world case, when the sintering temperature was set at 1600°C and the holding time was 6 hours, the refractory bricks had better density and strength. After 80 thermal shock cycles, the damage area was only about 20%. But when the temperature was 1500°C and the holding time was 4 hours, the damage area reached about 35% after the same number of cycles. This clearly shows that proper temperature control and holding time can significantly improve the thermal shock resistance of refractory bricks.

The thermal cycle frequency in the service environment can accelerate the thermal shock failure of refractory materials. In a steel plant where the thermal cycle frequency was high, the refractory bricks showed obvious signs of damage after only 30 thermal shock cycles. Through data analysis, it was found that the higher the thermal cycle frequency, the faster the crack propagation rate in the refractory bricks. This indicates that reducing the thermal cycle frequency or improving the refractory bricks' ability to resist high - frequency thermal cycles is essential.

Let's take a specific steel plant as an example. There were two types of refractory bricks with different formulations and processes used in the dry quenching system. One type, with a well - optimized raw material ratio, microstructure, and sintering process, had a much longer service life. After a year of operation, the damage degree of this type of refractory brick was only about 25%, while the other type with relatively poor design had a damage degree of about 50%. This case clearly demonstrates the importance of comprehensive optimization in the production of refractory bricks.

In conclusion, optimizing the raw material ratio, microstructure design, sintering process, and considering the service environment are all necessary steps to improve the thermal shock resistance of dry - quenching refractory bricks. By implementing these optimization strategies, steel plants can extend the service life of kiln linings, reduce the risk of unplanned shutdowns, and improve energy efficiency. Are you looking for high - quality refractory bricks with excellent thermal shock resistance? Click here to explore our advanced refractory brick solutions!