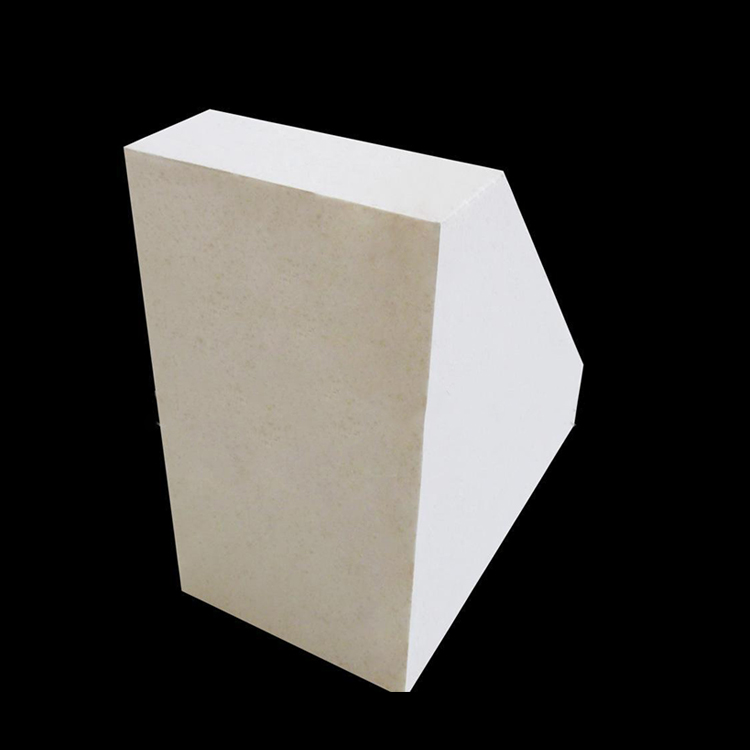

In the steel industry, the longevity and stability of furnace linings are crucial for efficient and safe production. High-performance andalusite refractory bricks have emerged as a game - changer in this field, offering significant improvements in furnace lining lifespan. This article delves into the key performance indicators of these bricks under rapid temperature change conditions, their manufacturing processes, and real - world case studies.

The performance of high - performance andalusite refractory bricks in high - temperature and rapid temperature change environments is evaluated through several core indicators. Cold crushing strength refers to the ability of the refractory brick to withstand pressure at room temperature. A high cold crushing strength ensures that the brick can maintain its integrity during handling and installation. High load - softening temperature is another critical factor. It represents the temperature at which the brick begins to deform under a specific load. For example, in a steel - making furnace, where heavy loads are common, a high load - softening temperature is essential to prevent the collapse of the furnace lining.

Creep resistance is the ability of the refractory brick to resist deformation over time under a constant load at high temperatures. In long - term high - temperature operations, such as in a continuous steel - making process, good creep resistance can prevent the brick from deforming and thus maintain the stability of the furnace lining. Thermal shock resistance is perhaps the most important property in a rapid temperature change environment. Steel - making furnaces often experience rapid heating and cooling cycles, and a refractory brick with high thermal shock resistance can withstand these cycles without cracking or spalling.

In different types of steel - making furnaces, such as converters, electric furnaces, and heating furnaces, these performance indicators have different impacts on the furnace lining lifespan and stability. In a converter, where the temperature changes rapidly during the blowing process, high thermal shock resistance is crucial. If the refractory brick cannot withstand the thermal stress, it may crack, leading to molten steel leakage and potential safety hazards. In an electric furnace, high load - softening temperature and creep resistance are more important because of the long - term high - temperature and high - load environment.

For heating furnaces, which are used for pre - heating steel billets, the ability to resist rapid temperature changes and maintain good cold crushing strength during repeated loading and unloading are key factors. By understanding these specific requirements, steel companies can choose the most suitable refractory bricks for their furnaces.

The manufacturing process of high - performance andalusite refractory bricks plays a vital role in enhancing their comprehensive performance. Through precise control of raw material proportions, firing systems, and microstructure regulation, the performance of the bricks can be significantly improved. For example, by carefully selecting the raw materials and adjusting their proportions, manufacturers can optimize the chemical composition of the bricks, which in turn affects their physical properties. The firing system, including the firing temperature and time, can also be adjusted to achieve the desired microstructure, such as a more uniform grain size distribution, which enhances the overall performance of the bricks.

Let's take a real - world case from a steel mill. Before replacing the furnace lining with high - performance andalusite refractory bricks, the furnace lining had a relatively short lifespan, often requiring frequent repairs and causing significant production downtime. After the replacement, the furnace lining lifespan increased by 40%. This not only reduced the risk of furnace shutdown but also improved the overall efficiency of the melting process. The steel mill was able to produce more steel with less interruption, resulting in substantial cost savings.

| Indicator | Before Replacement | After Replacement |

|---|---|---|

| Furnace Lining Lifespan | X months | 1.4X months |

| Downtime | Y days per year | 0.6Y days per year |

| Production Efficiency | Z tons per month | 1.2Z tons per month |

In conclusion, high - performance andalusite refractory bricks offer significant advantages in improving furnace lining lifespan and stability in the steel industry. However, choosing the right refractory bricks requires a deep understanding of the specific requirements of different furnaces and the performance indicators of the bricks. If you are a steel company facing challenges in furnace lining lifespan and efficiency, we recommend conducting a detailed analysis of your furnace operating conditions and considering high - performance andalusite refractory bricks. To learn more about the thermal shock resistance testing standards of these refractory bricks, click here.