The coke dry quenching (CDQ) system operates under extremely harsh conditions, characterized by severe high - temperature fluctuations, frequent start - stops, and slag erosion. These factors pose significant challenges to the selection of refractory materials. For instance, high - temperature fluctuations can cause thermal stress in refractory bricks, leading to cracking and spalling. Slag erosion can gradually corrode the surface of the refractory, reducing its thickness and integrity.

Let's break down the specific requirements of different workstations in the CDQ system. In the inclined passage area, the refractory materials need to have excellent thermal shock resistance due to the rapid change of gas flow and temperature. The cooling chamber requires materials with high heat - transfer efficiency and good resistance to slag penetration. At the coke discharge port, the refractory must withstand high - temperature abrasion and mechanical impact.

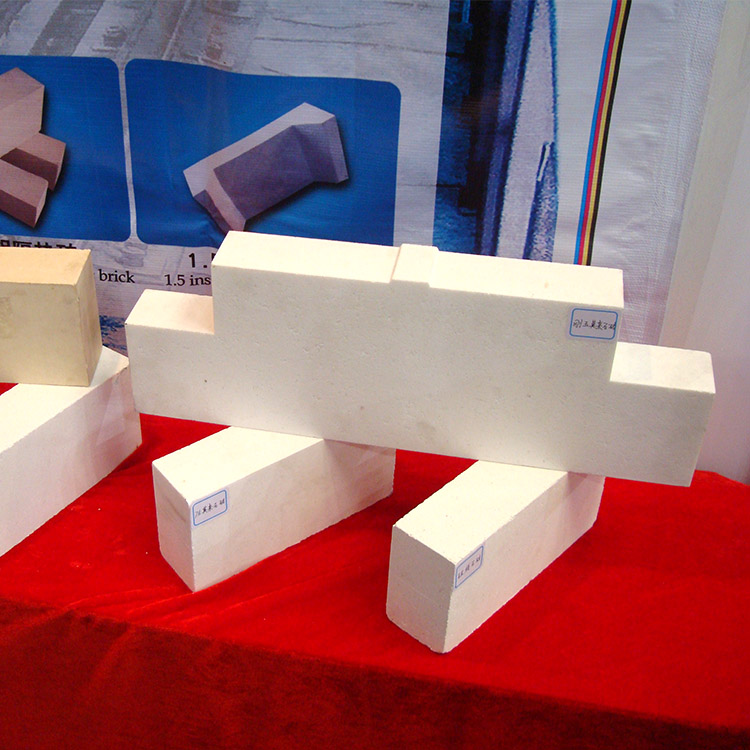

The use of a high - purity mullite matrix combined with micro - crystal strengthening technology can significantly enhance the thermal shock resistance of refractory bricks. The high - purity mullite matrix provides a stable structure, while the micro - crystal strengthening technology can effectively disperse thermal stress. When the temperature changes rapidly, the micro - crystals can absorb and release stress, preventing the formation and propagation of cracks.

The composite structure design of refractory bricks has many advantages. In practical applications, it can better adapt to the complex working conditions of the CDQ system. Compared with traditional single - structure refractory bricks, the composite structure can combine the advantages of different materials, improving both thermal shock resistance and slag erosion resistance. For example, in some CDQ systems, the use of composite - structured refractory bricks has extended the service life of the system by 30% - 50%.

Construction quality is a key factor affecting the overall service life of the CDQ system. Precise control of masonry joints and proper reservation of expansion joints are crucial. If the masonry joints are too large, it can lead to gas leakage and uneven heat distribution. Insufficient expansion joints can cause the refractory bricks to crack under thermal expansion. In a real - world project, a well - constructed CDQ system with strict attention to these details has shown a 20% longer service life compared to a poorly constructed one.

Let's look at some case studies. In a metallurgical enterprise, the traditional refractory bricks in the CDQ system needed to be replaced every 2 - 3 years due to poor thermal shock resistance and severe slag erosion. After replacing them with new high - alumina mullite refractory bricks, the replacement cycle was extended to 5 - 6 years, significantly reducing maintenance costs and improving the stability of the production process.

For metallurgical enterprise technical leaders, choosing the right refractory materials is crucial for the long - term operation of the CDQ system. If you want to learn more about how our high - alumina mullite refractory bricks can improve the stability and economy of your CDQ system, click here to get in touch with our experts.