High - alumina dense wear - resistant clay bricks are essential refractory materials widely used in high - temperature kilns. With alumina content typically ranging from 48% to 75%, these bricks can withstand extremely high temperatures from 1580°C to 1770°C. Their excellent wear - resistance and chemical stability make them ideal for harsh industrial environments, such as steelmaking, cement production, and glass manufacturing.

Before installing high - alumina dense wear - resistant clay bricks, several key preparations are necessary. First, a thorough inspection of the kiln structure is required to ensure its integrity. The surface where the bricks will be installed should be clean, flat, and free of any debris. Second, accurate measurement of the kiln dimensions is crucial to determine the quantity and layout of the bricks. Additionally, it is recommended to pre - sort the bricks according to their size and quality to ensure a uniform installation.

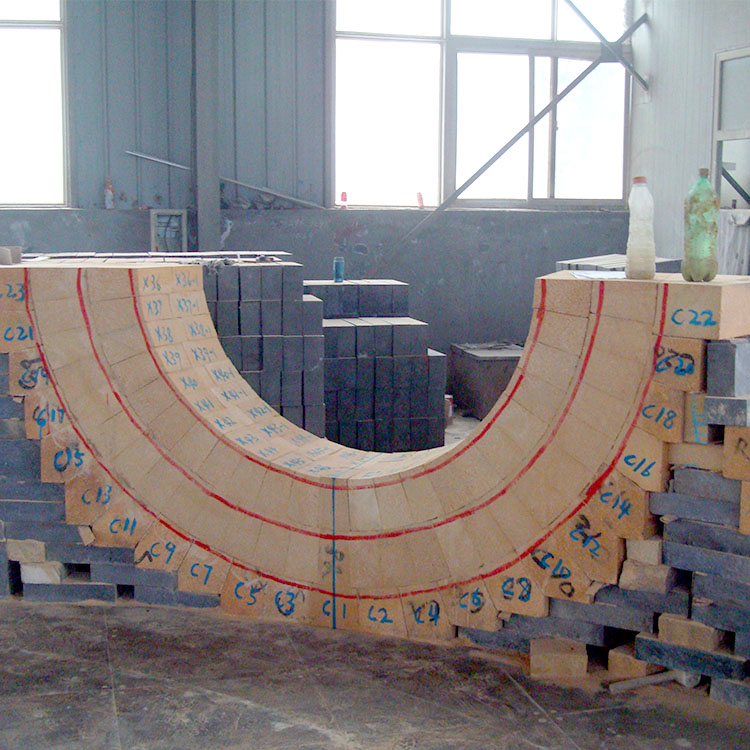

The installation of high - alumina dense wear - resistant clay bricks should be carried out in strict accordance with the alumina content and temperature parameters. For bricks with higher alumina content, they are more suitable for areas with higher temperature requirements. The layout of the bricks should follow a specific pattern to ensure the overall stability of the furnace lining. For example, a staggered joint arrangement can effectively enhance the structural strength of the lining. During the installation process, appropriate refractory mortar should be used, and the thickness of the mortar joint should be controlled within 2 - 3mm to ensure good heat - insulation and sealing performance.

In high - temperature extreme conditions (1580 - 1770°C), high - alumina dense wear - resistant clay bricks may face challenges such as thermal stress, wear, and chemical corrosion. To ensure their performance, it is necessary to optimize the design of the furnace lining structure. For example, using expansion joints can effectively relieve thermal stress. In terms of wear resistance, selecting bricks with high - hardness aggregates can improve the wear - resistance of the lining. Regarding chemical corrosion, understanding the chemical composition of the corrosive substances in the kiln and choosing bricks with corresponding chemical resistance are essential.

Regular detection of wear and chemical corrosion is crucial for the long - term operation of the furnace lining. Non - destructive testing methods, such as ultrasonic testing and infrared thermography, can be used to detect internal defects and wear conditions of the bricks. For chemical corrosion, analyzing the chemical composition of the surface layer of the bricks can help determine the degree of corrosion. The following table shows the general detection standards:

| Detection Item | Detection Method | Judgment Standard |

|---|---|---|

| Wear | Ultrasonic testing | If the thickness reduction exceeds 20% of the original thickness, replacement is required |

| Chemical Corrosion | Chemical analysis | If the content of corrosive substances exceeds 10% of the surface layer, take corresponding protective measures |

Regular maintenance is the key to ensuring the long - term performance of high - alumina dense wear - resistant clay bricks. A maintenance cycle of 3 - 6 months is recommended. During maintenance, damaged bricks should be replaced in time, and the refractory mortar joints should be inspected and repaired. Additionally, monitoring the temperature and pressure inside the kiln can help detect potential problems in advance.

Combining industry standards and practical experience is essential for improving furnace lining management. For example, in a steelmaking plant, by following the installation and maintenance methods described above, the service life of the furnace lining was extended by 30%, and the production efficiency was significantly improved. These practical cases provide valuable references for technical personnel in the industry.

In conclusion, high - alumina dense wear - resistant clay bricks play a vital role in high - temperature industrial applications. By following the correct installation, maintenance, and detection methods, technical personnel can effectively improve furnace lining management levels, ensuring the efficient and safe operation of equipment. If you are interested in our high - alumina dense wear - resistant clay bricks and related technical support, please click here to contact us for more information.