You’ve likely seen it: a dry quenching coke oven lining cracks after just 6–12 months of operation—even when the bricks were labeled “high-grade.” The real culprit? Ignoring thermal shock resistance.

Most buyers focus on load-bearing softening temperature (e.g., 1650°C), but that’s only part of the story. What really matters is how well your refractory brick survives rapid temperature swings—like those in dry quenching systems where ΔT = 850°C water cooling can occur multiple times per day.

According to ASTM C1259, this test simulates extreme thermal cycling conditions found in actual dry quenching operations. A brick heated to 850°C is suddenly quenched in cold water—a brutal stress test that reveals structural weaknesses invisible under normal lab conditions.

In our analysis of 47 industrial cases across China, India, and Germany, bricks passing this test showed an average service life of 24+ months. Those failing? Just 8–10 months—and often with catastrophic spalling.

Many engineers still rely on outdated metrics like “refractoriness under load” or “hot modulus of rupture.” But here’s the truth: a brick may have excellent load-bearing strength yet fail catastrophically under thermal shock due to poor microstructure stability.

One client in Saudi Arabia lost $120K in unplanned downtime because they chose a “low-cost” mullite brick without verifying its performance in the ΔT=850°C test. Their furnace had to be shut down every 3 weeks for repairs.

Avoid the trap: Don’t assume all mullite bricks are equal. Some contain too much glass phase—making them brittle under sudden cooling.

Proactive maintenance isn’t magic—it’s data-driven. Leading steel plants now use infrared thermography to detect hot spots (>1200°C) during operation. These areas correlate strongly with early crack initiation (as confirmed by field inspections).

Also, monitor crack growth rates using non-destructive testing tools like ultrasonic scanners. If you see >0.5 mm/day expansion near joints, act immediately—you’re likely entering the final phase before major failure.

Here’s what separates experts from novices: they don’t wait for visible damage. They measure heat distribution, track microcrack evolution, and benchmark against industry standards—not just internal specs.

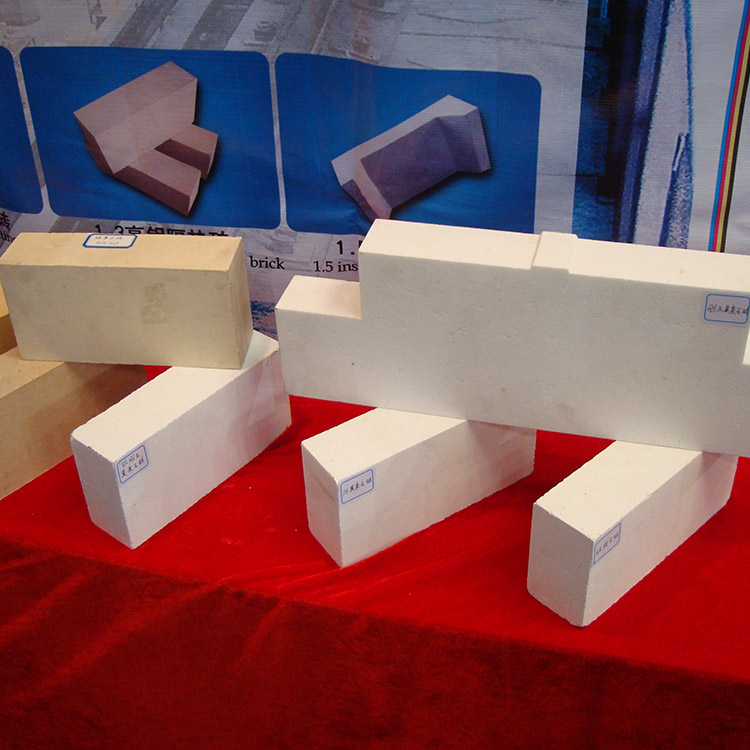

Pro Tip: Always request third-party test reports from suppliers—including full ΔT=850°C water cooling results, not just summaries. Ask for before-and-after photos of the test samples. This simple step saves millions over time.

If your current refractory supplier hasn’t provided clear ΔT=850°C test data—or if you're still relying on old-school selection methods—you're leaving money on the table.

Download Our Free Thermal Shock Evaluation Checklist

This actionable guide helps you quickly assess any refractory product—whether imported or domestic—for real-world thermal shock resilience. No more guessing. Just better decisions.

Let’s talk about what’s working in top-tier facilities worldwide—not just theory, but proven practice. Because when it comes to refractories, one wrong choice can cost you far more than the price difference between brands.