In today’s competitive steel industry, furnace efficiency isn’t just about output—it’s about minimizing downtime and maximizing refractory life. Traditional high-alumina bricks, once the go-to solution for molten metal environments, are now showing their age under rapid thermal cycling conditions. That’s where red mullite brick enters the equation—not as a replacement, but as a performance leap.

Steel plants operating with frequent heating/cooling cycles—such as those in electric arc furnaces (EAFs) or ladle refining—often see furnace linings fail after only 6–8 weeks. According to a 2023 study by the International Refractories Association, over 60% of unplanned maintenance in steel melting units stems from thermal shock-induced cracks in traditional high-alumina bricks.

| Performance Metric | High-Alumina Brick | Red Mullite Brick |

|---|---|---|

| Cold Strength (MPa) | 70–90 | 120–150 |

| Thermal Shock Resistance (ΔT) | ≤ 600°C | ≥ 850°C |

| Load Softening Temp (°C) | 1500–1550 | 1600–1650 |

| Creep Resistance @ 1400°C | Moderate | Excellent |

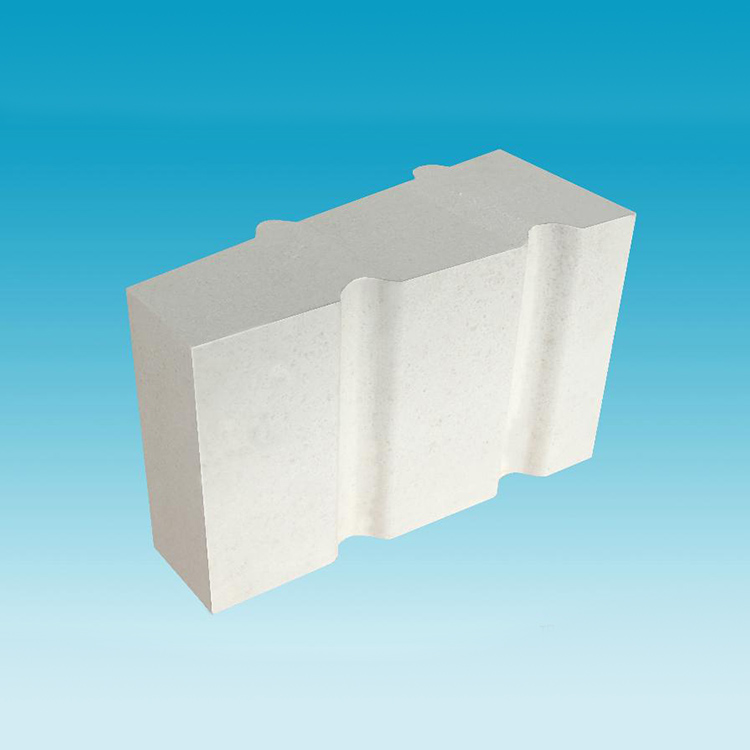

Unlike conventional high-alumina bricks that rely on dense alumina phases prone to microcracking during temperature swings, red mullite features a unique interlocking crystal lattice formed by aluminum silicate (Al₄Si₂O₁₀). This structure absorbs thermal stress more evenly—like a sponge distributing pressure rather than cracking under it. The result? A 30–50% longer service life in real-world EAF operations, backed by case studies from major mills in China, India, and Brazil.

One client in Southeast Asia reported reducing furnace lining replacements from every 7 weeks to every 14 weeks after switching to red mullite. Their average repair cost dropped by 42%, and energy consumption per tonne of steel fell by 5% due to improved heat retention.

While red mullite excels in fast-cycling applications, it’s not a one-size-fits-all solution. It performs best when used in zones with moderate chemical attack—such as sidewalls or roof linings—and should be paired with proper installation practices and regular inspection protocols.

For plant engineers looking to reduce operational risk while boosting productivity, this is no longer just an option—it’s a strategic upgrade path. Whether you're managing a small-scale foundry or a large integrated mill, understanding how red mullite addresses your specific thermal challenges can make all the difference.

Ready to explore how red mullite can transform your furnace performance? Get our free “Steel Furnace Refractory Selection Guide”—a concise yet powerful resource designed for technical managers who want smarter, faster decisions without sacrificing reliability.

Download Your Free Refractory Selection Guide Now