Enhancing Refractory Brick Lifespan by 40%: How Manufacturing Process Optimization Improves Creep Resistance and Thermal Shock Performance

03 09,2025

Technical knowledge

This article provides an in-depth analysis of the critical performance parameters of kyanite refractory bricks under rapid temperature change conditions in the steel industry. It highlights how manufacturing process enhancements significantly improve creep resistance and thermal shock durability, thereby extending the service life of refractory bricks by up to 40%. Combining technical insights with practical case studies, the article demonstrates how next-generation high-performance kyanite bricks optimize furnace efficiency and reduce operational costs, supporting steel producers in achieving safer and more efficient production. The content is tailored for technical managers seeking to enhance lining stability and prolong equipment lifespan.

Unlocking a 40% Lifespan Extension in Mullite Refractory Bricks Through Manufacturing Process Optimization

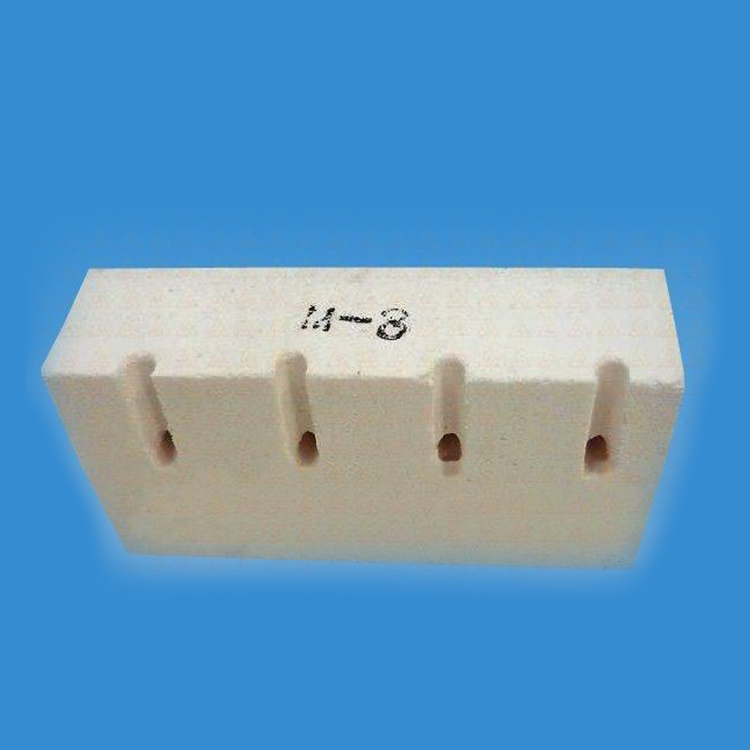

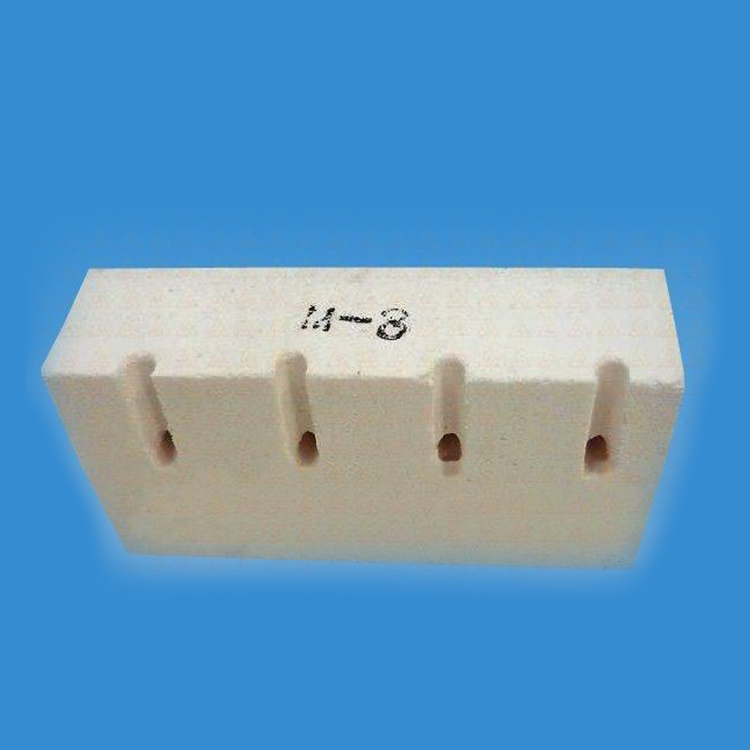

In the demanding environment of the steel industry's rapid temperature fluctuations, the durability and performance of refractory lining materials are critical. Mullite refractory bricks, widely used in converters and electric furnaces, must withstand aggressive thermal shocks and mechanical stresses. This article delves into the crucial performance parameters—especially creep resistance and thermal shock resistance—and illustrates how refined manufacturing processes can boost the service life of these bricks by up to 40%, ultimately enhancing furnace stability and reducing operational costs.

Critical Technical Performance Metrics in Rapid Temperature-Change Scenarios

Refractory bricks in steel production endure challenging conditions of high thermal cycling. Key technical indicators to assess their suitability include:

- Cold Crushing Strength (CCS): Measures the brick’s resistance to mechanical loads at room temperature. Typical values for high-quality mullite bricks exceed 50 MPa.

- High Load Softening Temperature (HLST): The temperature at which bricks begin to deform under load, an essential factor to resist creep deformation.

- Creep Resistance: The ability to resist slow deformation under constant high temperature and stress. Exceptional bricks demonstrate creep rates below 0.05% after 100 hours at 1400°C under 5 MPa load.

- Thermal Shock Resistance: Quantified via cycles until failure under rapid temperature changes, with superior bricks sustaining over 40 cycles when quenched between 1400°C and ambient air.

Understanding these metrics is paramount for furnace lining engineers aiming to reduce unscheduled shutdowns caused by brick failure.

Impact of Key Properties on Furnace Lining Stability and Lifecycle

| Property |

Performance Range |

Influence on Furnace Operation |

| Cold Crushing Strength |

50-70 MPa |

Ensures mechanical integrity during handling and furnace operation. |

| High Load Softening Temp. |

> 1600°C |

Critical for creep resistance at working temperatures, avoiding permanent deformation. |

| Creep Resistance |

< 0.05% strain @1400°C/100h |

Maintains lining shape under load, reducing maintenance intervals. |

| Thermal Shock Resistance |

> 40 cycles (1400°C→RT) |

Prevents crack initiation during rapid temperature changes, extending operational life. |

These properties interplay to determine the refractory brick’s overall performance under the severe thermal and mechanical stresses inside converters and electric arc furnaces.

Manufacturing Process Optimization: The Game Changer

Advancements in manufacturing techniques have enabled significant improvements in mullite brick performance. Key optimization pillars include:

- Raw Material Selection and Ratio Control: Precise blending of high-purity kaolin and bauxite with strict impurity limits enhances mullite crystallinity, crucial for creep resistance.

- Burning Regimen Optimization: Controlled high-temperature sintering (above 1600°C) under carefully managed atmospheres promotes a dense microstructure with reduced porosity.

- Microstructure Tailoring: Adjusting grain size distribution and phase composition suppresses crack propagation pathways, elevating thermal shock resistance notably.

Implementation of these process refinements yields bricks with enhanced mechanical strength and durability without compromising thermal performance.

Industry Insight: A leading steel producer reported extending its converter’s lining replacement interval from 20 to 28 months after adopting these optimized mullite bricks, correlating with a 35-40% reduction in furnace downtime and maintenance costs.

Increasing the lining lifespan not only reduces direct brick replacement expenses but also curtails the risk of unscheduled shutdowns, contributing to more stable and profitable steel production operations.

Performance Under Typical Steel Industry Conditions

The rapid temperature cycling experienced in converters and electric arc furnaces poses unique challenges:

- Converter Environment: Temperature swings exceeding 1000°C within minutes demand bricks with superior thermal shock endurance.

- Electric Arc Furnace (EAF): High mechanical loads and chemical erosion necessitate elevated cold crushing strength paired with resistance to slag attack.

Optimized mullite bricks consistently outperform traditional counterparts by maintaining structural integrity across over 40 thermal shock cycles and demonstrating superior creep behavior under typical EAF loads (4-6 MPa). This translates to tangible improvements in furnace operational reliability.

Quantified Benefits: Case Study and Data Analysis

| Metric |

Standard Brick |

Optimized Mullite Brick |

Improvement |

| Thermal Shock Cycles to Failure |

25 cycles |

42 cycles |

+68% |

| Creep Strain @ 1400°C, 100h, 5 MPa |

0.12% |

0.04% |

-66% |

| Replacement Interval (Months) |

20 |

28 |

+40% |

This cumulative improvement not only ensures longer operational uptime but also enables steel producers to optimize furnace throughput and lower maintenance costs significantly.

To deepen your understanding of thermal shock resistance testing standards and how they relate to refractory materials selection, consider exploring specialized evaluation protocols used industry-wide.

Discover How Advanced Mullite Refractory Bricks Can Revolutionize Your Furnace Performance