In the coke dry quenching (CDQ) system, refractory bricks are frequently exposed to extreme thermal shocks. The thermal shock resistance of refractory bricks directly determines the lining life and operational safety of the system. This article conducts a comprehensive technical analysis from four key dimensions: raw material ratio, microstructure, manufacturing process, and service environment.

The ratio of mullite to corundum in high - alumina mullite refractory bricks is a crucial factor affecting thermal shock resistance. A higher proportion of mullite generally provides better thermal shock resistance, but it may reduce the overall strength. For example, in a typical CDQ system, when the mullite content increases from 50% to 70%, the number of thermal shock cycles the refractory brick can withstand increases by about 30%. However, the compressive strength may decrease by about 15%. By adjusting the raw material ratio, manufacturers can balance the thermal shock resistance and mechanical properties of the refractory bricks.

The pore distribution and grain boundary strength in the microstructure of refractory bricks also play important roles. A well - designed pore distribution can effectively absorb thermal stress. For instance, a uniform distribution of small pores with a diameter of 1 - 3 microns can increase the thermal shock resistance by approximately 25%. Additionally, strong grain boundaries can prevent crack propagation. Through advanced microscopic structure design, the internal stress of the refractory brick during thermal cycling can be better released, thereby improving its thermal shock resistance.

The sintering process, including temperature gradient and holding time, has a significant impact on the thermal shock resistance of refractory bricks. A proper temperature gradient during sintering can ensure a uniform internal structure of the brick. For example, in a sintering process with a temperature gradient of 10 - 15°C per hour, the thermal shock resistance of the refractory brick can be improved by about 20%. Moreover, an appropriate holding time can enhance the density and strength of the brick. By strictly controlling the manufacturing process, the quality and thermal shock resistance of the refractory bricks can be effectively improved.

The thermal cycling frequency in the service environment is another key factor. In a CDQ system with a high - frequency thermal cycling environment, the thermal shock resistance requirements for refractory bricks are much higher. For example, in a system with a thermal cycling frequency of more than 10 times per day, the refractory bricks need to have excellent thermal shock resistance. Through real - world case studies, it has been found that under such high - frequency thermal cycling conditions, the service life of refractory bricks with poor thermal shock resistance is only about 1 - 2 years, while those with good thermal shock resistance can reach 3 - 5 years.

Let's take a look at some typical failure cases. In a certain metallurgical plant, due to improper selection of refractory bricks, the CDQ system experienced frequent non - planned shutdowns. By analyzing the failed refractory bricks, it was found that the main reason was the low thermal shock resistance caused by an improper raw material ratio and poor manufacturing process. Through a comparison of different refractory brick products in actual service, it was found that products with a reasonable raw material ratio, well - designed microstructure, and strict manufacturing process had better thermal shock resistance and longer service life.

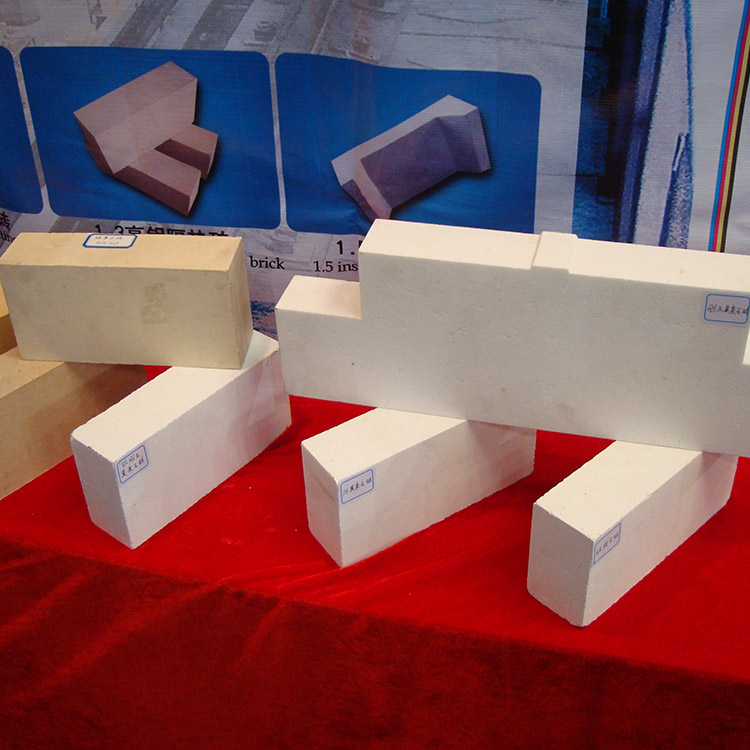

To optimize the use of refractory bricks in CDQ systems, a series of optimization suggestions from material selection to construction are put forward. In terms of material selection, metallurgical engineers should comprehensively consider the raw material ratio, microstructure, and manufacturing process of refractory bricks. During the construction process, proper installation methods should be adopted to ensure the tightness and stability of the refractory lining. By following these optimization suggestions, the service life of the kiln can be effectively extended, and the risk of non - planned shutdowns can be reduced.

Choosing the right refractory bricks is not just a purchase; it's an investment for long - term stable operation. Are you ready to make the best choice for your CDQ system?

Explore High - Quality Refractory Bricks Now