In dry quenching systems, refractory bricks are constantly exposed to extreme thermal shocks—especially during the rapid cooling phase when hot coke enters the chamber. This repeated stress often leads to spalling, unplanned downtime, and significant operational losses.

Based on field data from over 30 steel plants worldwide, we’ve identified five key factors that directly influence the anti-thermal shock performance of high-alumina mullite refractories:

A balanced mix of mullite (Al6Si2O13) and corundum (Al2O3) is critical. In one case study at a Chinese steel mill, switching from a 70/30 to an 80/20 ratio increased thermal cycle resistance from 150 to 320 cycles before visible spalling—a 113% improvement in service life.

Optimal pore size distribution (average 5–15 μm) helps absorb internal stresses without compromising structural strength. Field observations show that bricks with uniform micropores (<10 μm) exhibit up to 40% less surface cracking after 200 thermal cycles compared to those with irregular porosity.

Rapid heating or uneven temperature gradients during sintering can create microcracks. Our engineers recommend a controlled ramp rate of ≤5°C/min above 1200°C. One Indian plant reported a 60% reduction in early-stage failures after adopting this practice.

The frequency of heat-up and cool-down cycles significantly impacts wear. At a Korean facility, reducing daily cycling from 8 to 5 times led to a 27% increase in lining lifespan—an average savings of $28,000 per month in maintenance costs.

“Thermal shock isn’t just about temperature—it’s about how fast the brick can handle it. We now test our materials using real-time load simulation, not just lab tests.” — Dr. Lin Wei, Senior Refractory Engineer, Baosteel R&D Center

Even the best material fails if installed improperly. A Brazilian steel company lost 72 hours of production due to poor mortar application and insufficient expansion joints—costing over $500,000. Proper installation practices reduce failure risk by up to 65%.

Whether you're a metallurgical engineer, plant manager, or procurement specialist, these insights offer actionable steps to improve your dry quenching system’s reliability—without costly redesigns or replacements.

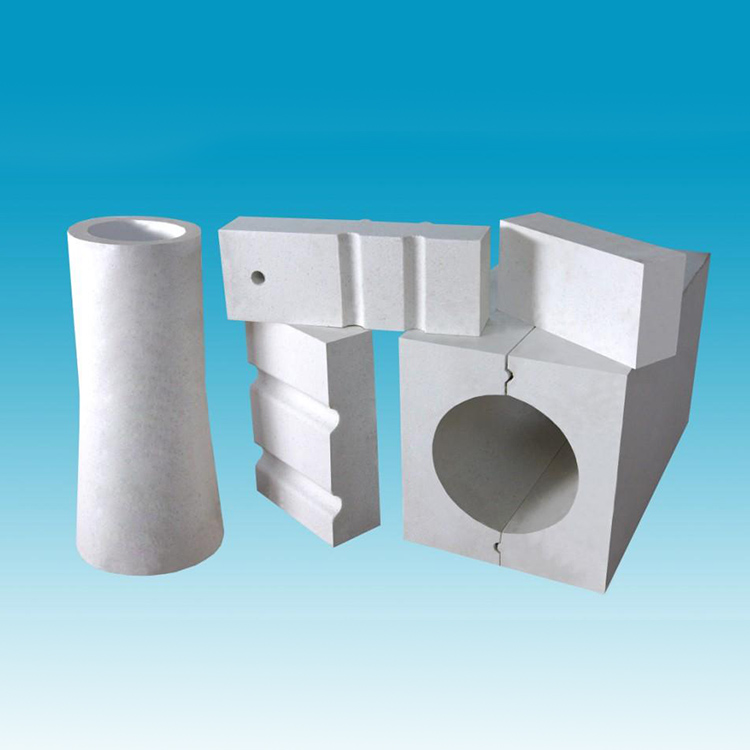

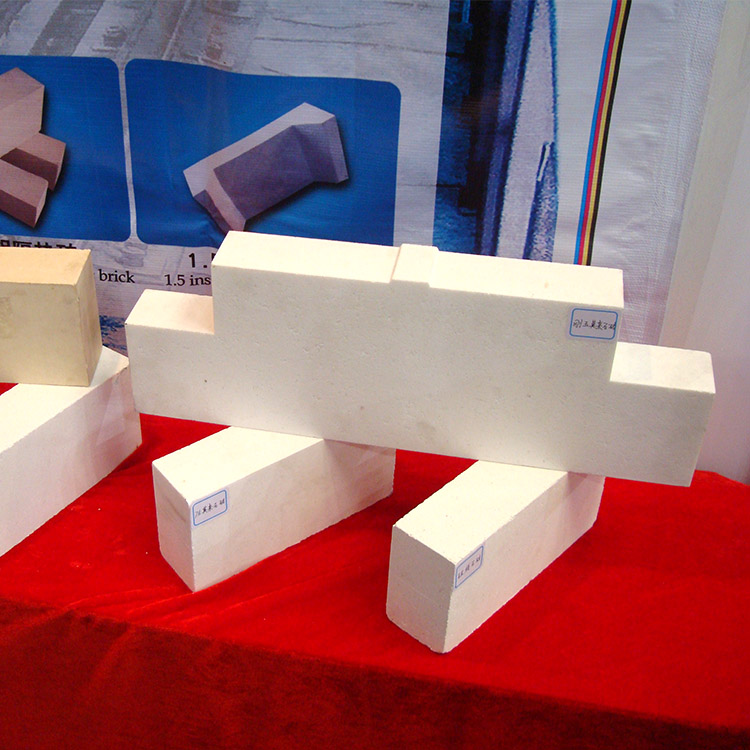

Explore our high-performance High-Alumina Mullite Refractories engineered for extreme thermal cycling environments.

Get Your Free Technical Brochure Now →