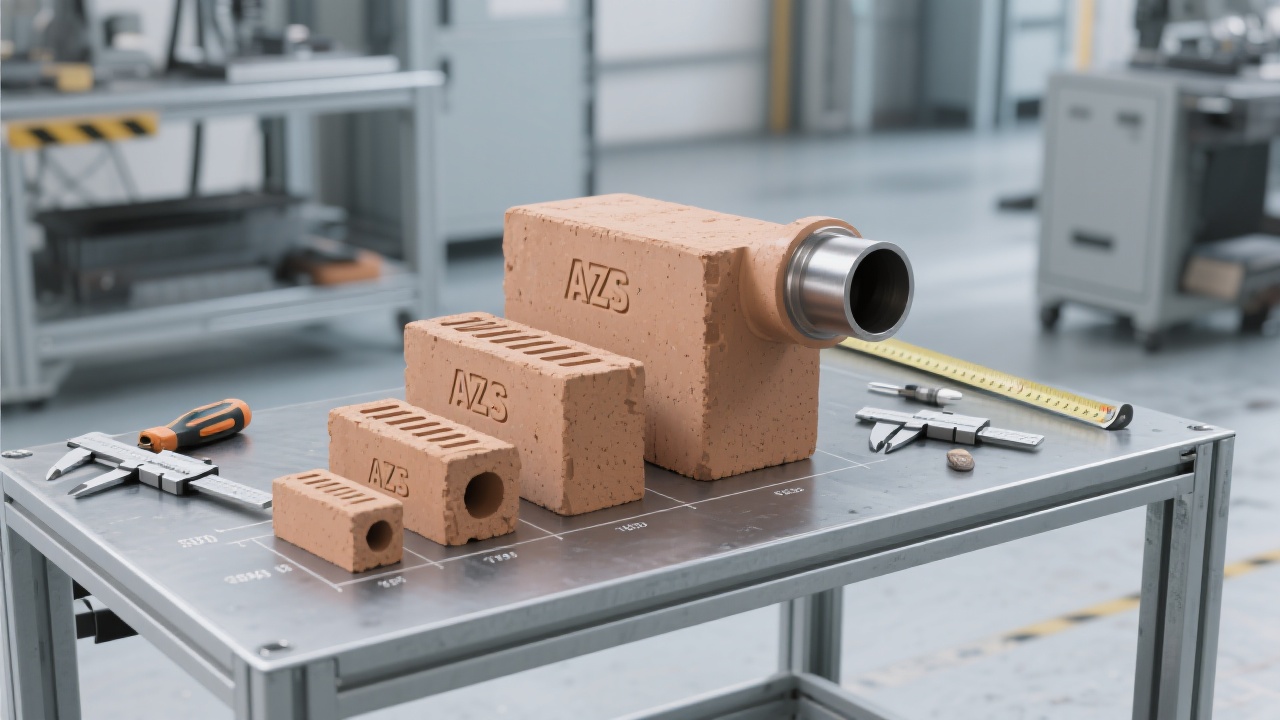

In high-temperature industrial environments like steelmaking, furnace lining integrity directly impacts safety, efficiency, and cost control. Red column stone (andalusite) refractory bricks have emerged as a top choice for rapid thermal cycling applications due to their superior resistance to creep and thermal shock — key factors that influence both operational uptime and long-term profitability.

Unlike conventional fireclay or silica bricks, andalusite-based refractories exhibit exceptional stability under sudden temperature changes. According to field data from European steel plants, these bricks maintain structural integrity through over 500 thermal cycles without significant cracking — compared to just 200–300 cycles for standard options. This performance is rooted in their unique microstructure: when heated, andalusite undergoes controlled phase transformation into mullite, which enhances strength and minimizes expansion stress.

| Property | Andalusite Brick | Standard Fireclay |

|---|---|---|

| Thermal Shock Resistance (°C) | ≥ 1000 | ~600 |

| Creep Resistance at 1400°C (h) | > 1000 hrs | ~300 hrs |

| Average Service Life (months) | 18–24 | 8–12 |

Even the best material fails if improperly installed. Key considerations include:

One Chinese steel mill reported a 40% increase in lining life after switching to certified andalusite bricks and implementing a standardized installation checklist. Their maintenance team now performs weekly visual inspections, capturing thermal images to detect early signs of micro-cracking — an approach recommended by leading refractory engineers globally.

A structured maintenance plan includes monthly thickness checks via ultrasonic testing, quarterly inspection of joints for spalling, and annual review of operating parameters such as cooling rate and charge loading patterns. For example, one Middle Eastern client reduced unplanned outages by 65% after adopting this schedule — translating to ~$150K/year in avoided production losses.

By embedding these practices into daily operations, technical teams not only extend refractory life but also build institutional knowledge that supports continuous improvement. The result? A safer, more efficient furnace — and a stronger competitive edge.

Download Our Free Maintenance Checklist for Andalusite Refractory Bricks