In the demanding environment of dry quenching (DQ) systems, refractory bricks face extreme thermal shocks—from ambient temperatures up to over 1,000°C during coke discharge cycles. Many steel plants have experienced premature brick failure due to poor heat shock resistance, leading to costly unplanned shutdowns and safety risks.

Standardized lab tests like ASTM C1702 and ISO 1889 provide reliable benchmarks for evaluating refractory performance under rapid temperature changes. For example, high-alumina mullite bricks typically show a crack initiation threshold above 800°C with less than 5% mass loss after 10 thermal cycles—a clear advantage over traditional fireclay bricks that often fail at 500°C.

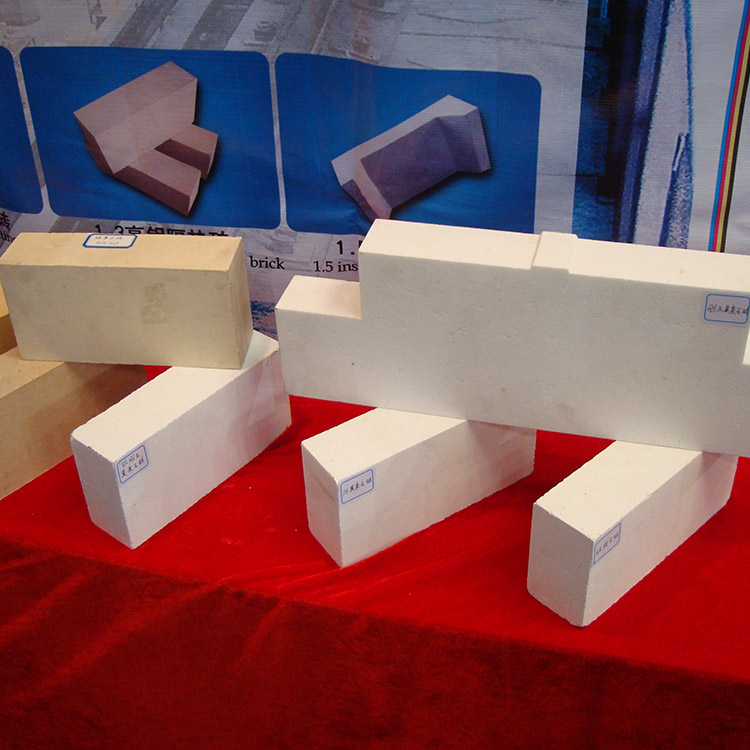

A real-world case from a Chinese steel mill illustrates this clearly: after replacing old zirconia-alumina bricks with our high-alumina mullite solution, they recorded zero visible cracks or spalling over six months of continuous operation—even with daily cycling between 20°C and 950°C.

Many buyers rely solely on bulk density or compressive strength when selecting refractories—ignoring critical heat shock indicators such as thermal expansion coefficient and fracture toughness. One European plant lost 3 weeks of production because their “high-strength” bricks cracked within 30 days due to unoptimized microstructure.

Our engineers now use infrared thermography to detect early-stage thermal stress buildup—before visible cracks appear. This proactive approach helps avoid unexpected downtime and extends refractory life by 30–50% compared to reactive maintenance models.

Steel producers aren’t just buying materials—they’re investing in operational continuity. In one U.S. facility, switching to high-alumina mullite reduced annual refractory replacement costs by $120,000 while improving furnace uptime by 18%. These results come from precise material selection backed by both lab data and field validation.

If you're still relying on outdated refractory specs or reacting only after failures occur, it's time to rethink your strategy. We’ve compiled an exclusive technical guide—“How to Evaluate Refractory Heat Shock Performance Like a Plant Engineer”—with detailed test protocols, failure analysis checklists, and real-case comparisons.

Get actionable insights from top-tier refractory engineers who've optimized dry quenching systems worldwide.

👉 Download the Free Guide