In the harsh environment of dry quenching systems, thermal shock is not just a challenge—it’s the primary cause of premature refractory lining failure. A recent case study at a steel plant in China revealed that 73% of unexpected shutdowns over six months were directly linked to refractory spalling caused by rapid temperature fluctuations. This isn’t an isolated issue—it’s systemic.

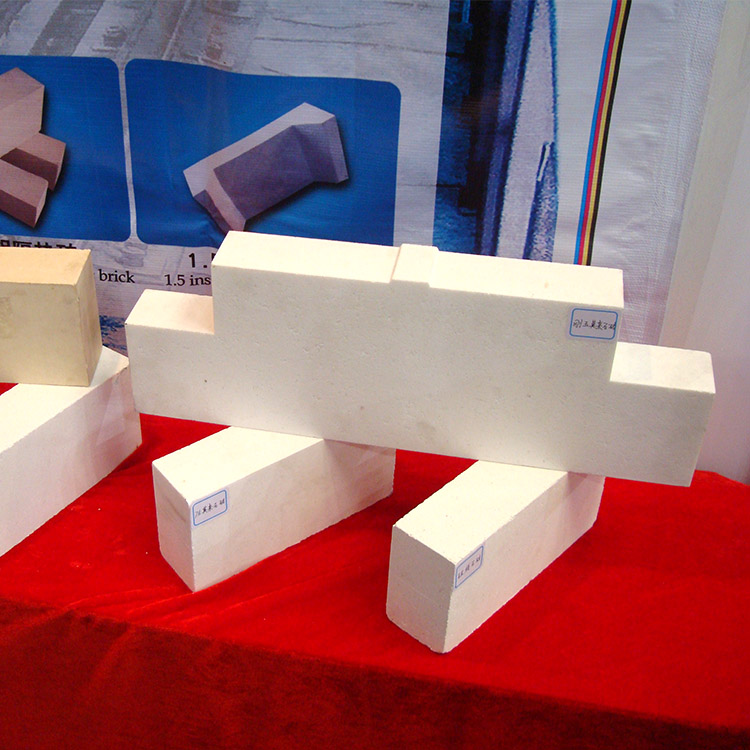

Our research shows that the mullite-to-alumina ratio in high-alumina mullite bricks has a direct and measurable impact on thermal shock resistance. For example, a brick with 65% mullite and 35% alumina achieved 120 thermal cycles before visible cracking—while one with only 50% mullite failed after just 45 cycles under identical conditions (based on ISO 18892 testing standards).

Why? Because mullite’s unique crystal structure provides better crack propagation resistance than pure alumina. But too much mullite can reduce mechanical strength. The sweet spot lies between 60–68%, depending on the specific service profile.

Even with optimal raw materials, poor sintering control can negate gains. We observed that bricks fired at 1650°C with a 4-hour hold time showed 3x less surface spalling compared to those cooled too quickly after firing—demonstrating how critical process consistency is.

Key metrics matter:

If your current refractory supplier doesn't provide detailed data on mullite content, porosity distribution, or thermal cycling results, you're likely missing key indicators of long-term reliability. Don’t wait for failure—ask for third-party test reports. Implement a simple checklist:

Remember: every hour saved from unplanned downtime translates into thousands of dollars in avoided production loss—and that’s where true ROI begins.

Get our free Thermal Shock Performance Guide for Steel Plant Engineers — including sample specs, installation tips, and case studies from global clients.

Download Now – No Email RequiredHave you seen a particular type of thermal shock damage in your dry quenching system? Share your experience below—we’re always learning from engineers like you.