In the demanding environment of dry quenching systems in steel plants, high alumina mullite refractory bricks routinely face rapid temperature fluctuations that cause severe thermal shock damage. Frequent cracking and spalling not only result in unexpected furnace shutdowns but also drive up expensive maintenance costs. This article presents an in-depth technical guide tailored for metallurgical engineers seeking to extend refractory lifespan through microstructural optimization. By focusing on key factors such as raw material ratios (mullite-to-corundum balance), pore morphology, grain boundary strength, and firing parameters, this tutorial delivers practical insights backed by real-world thermal cycling data. Mastering these details can keep your furnaces running longer and profitably — reducing downtime by days and boosting operational margins.

Dry quenching of coke subjects refractory linings to drastic and rapid temperature changes, often ranging from ambient to over 1400°C within minutes. This thermal cycling generates intense mechanical stresses that induce microcracks, ultimately propagating to macroscopic fractures leading to surface spalling. In many facilities, thermal shock failures are responsible for up to 30% of unplanned outages, with repair costs escalating beyond $250,000 per incident. Identifying root causes at the microstructure level is essential for engineering bricks that withstand such conditions.

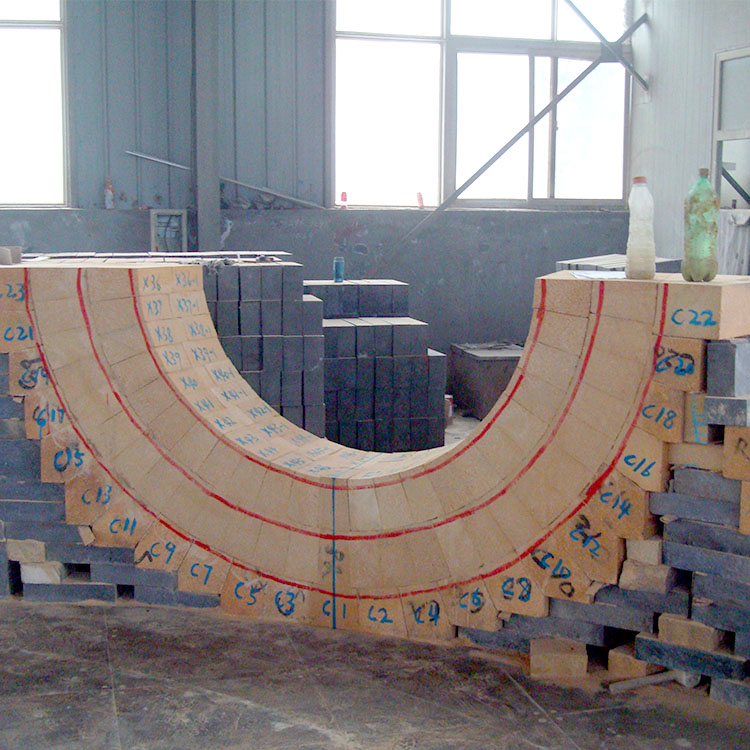

The performance of high alumina mullite bricks comes down to four interrelated factors:

Increasing mullite content improves the brick’s structural integrity and thermal shock resistance due to mullite’s lower thermal expansion coefficient (~5.5×10−6/K) compared to corundum (~7.5×10−6/K). However, an excessive mullite fraction may reduce mechanical strength, so the industry benchmark is maintaining a 60–75% mullite to corundum ratio to optimize crack resistance while sustaining load-bearing capacity.

Porosity is a double-edged sword in refractory bricks. A carefully engineered pore network can act as crack arrestors, dissipating stress and enhancing thermal shock resistance, but excessive or irregular pores create stress concentration points that exacerbate fracture.

Ideal Pore Characteristics:

The sintering profile directly impacts grain size and pore morphology. Controlled firing at temperatures of 1600–1650°C with slow heating (<3°C/min) and soaking (4–6 hours) promotes balanced densification and prevents abnormal grain growth. This leads to improved grain boundary cohesion—a critical factor in resisting thermal shock cycles exceeding 1000 cycles without significant degradation.

Comparative studies conducted at operational quenching sites reveal that optimized bricks withstand on average 25% more thermal shock cycles and exhibit 30% less surface spalling area than conventional formulations. For example, the optimized microstructure retained integrity through 1200 rapid thermal cycles (temperature jumps from 200°C to 1400°C within 5 minutes), while standard bricks failed by 900 cycles.

Material Selection: Ensure raw materials have matched thermal expansion and purity to minimize internal stresses.

Microstructure Engineering: Utilize additives and controlled pore formers to achieve uniform pores and strong grain boundaries.

Firing Protocol: Follow defined slow heating and soaking schedules to optimize densification.

Installation & Maintenance: Expertly install bricks to limit mechanical damage and monitor thermal cycling patterns to schedule timely inspections.

How does your facility approach refractory brick selection and thermal shock management? Share your experiences or questions below to advance the conversation.