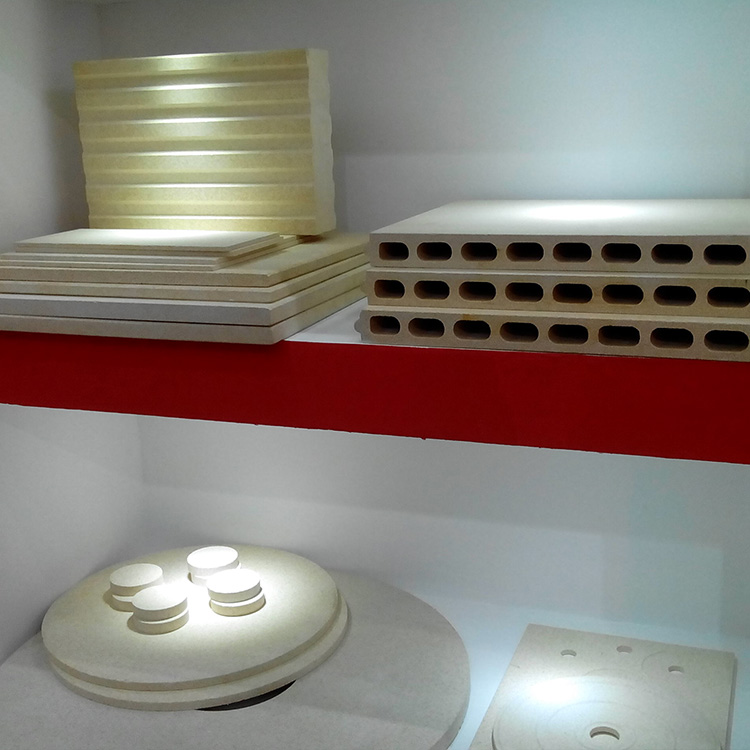

For industrial buyers in steel, cement, and petrochemical sectors, selecting the right refractory brick isn’t just about material strength—it’s about optimizing lifecycle costs. Among the many variables, aluminum oxide (Al₂O₃) content stands out as a critical performance lever. But here’s what most suppliers don’t tell you: it’s not always “more is better.” The sweet spot—30% to 46% Al₂O₃—is where durability meets efficiency.

At lower Al₂O₃ levels (<30%), bricks behave like old friends who wear out quickly under pressure—they resist thermal shock well but lack the hardness needed for abrasive environments. In contrast, bricks with >50% Al₂O₃ may seem stronger, but they’re brittle and prone to spalling when subjected to rapid temperature changes—a common issue in blast furnaces or coke ovens.

| Al₂O₃ Range | Key Performance Traits | Best Use Cases |

|---|---|---|

| 30–46% | Balanced toughness, low wear, excellent thermal shock resistance | Steel ladles, rotary kilns, fluidized bed reactors |

| <30% | Good thermal insulation, poor abrasion resistance | Low-temp insulation linings |

| >50% | High refractoriness, high brittleness | Static high-temp zones only |

In real-world applications, we’ve seen customers using 35–42% Al₂O₃ bricks reduce furnace downtime by up to 27% over two years compared to standard clay bricks. One cement plant in Saudi Arabia reported a 34% drop in maintenance labor costs after switching from 25% to 38% Al₂O₃ bricks—without increasing initial purchase price.

Many procurement teams assume higher Al₂O₃ means better quality—a myth that leads to overspending on materials that fail prematurely. Our lab tests show that bricks with 48% Al₂O₃ can crack within 12 months in intermittent heating cycles, while those at 40% maintain structural integrity for over 3 years under similar conditions.

This isn't just theory—it's how we help clients achieve measurable ROI. For example, a European steel mill saved €86,000 annually by choosing the correct Al₂O₃ level based on actual process temperatures and mechanical stress profiles—not just specs on paper.

When evaluating your next refractory order, ask: What’s the true cost per hour of operation—not just per ton? A smart choice in Al₂O₃ content can mean fewer replacements, safer operations, and more predictable production schedules.

Let us help you match your specific process needs with the optimal refractory solution—no guesswork, no wasted investment.

Get a free technical consultation tailored to your application—whether it’s steelmaking, refining, or ceramics.

Download Our Free Refractory Selection Guide