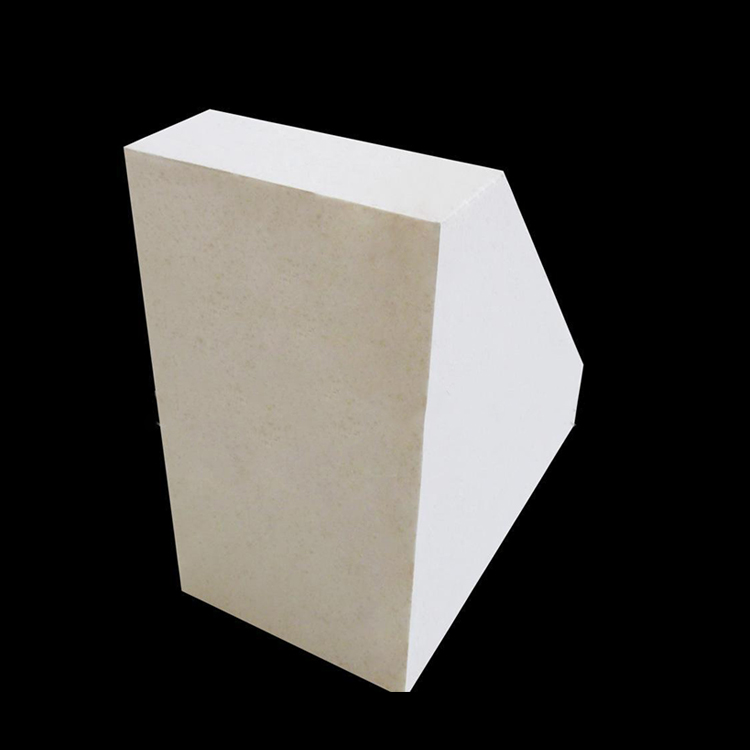

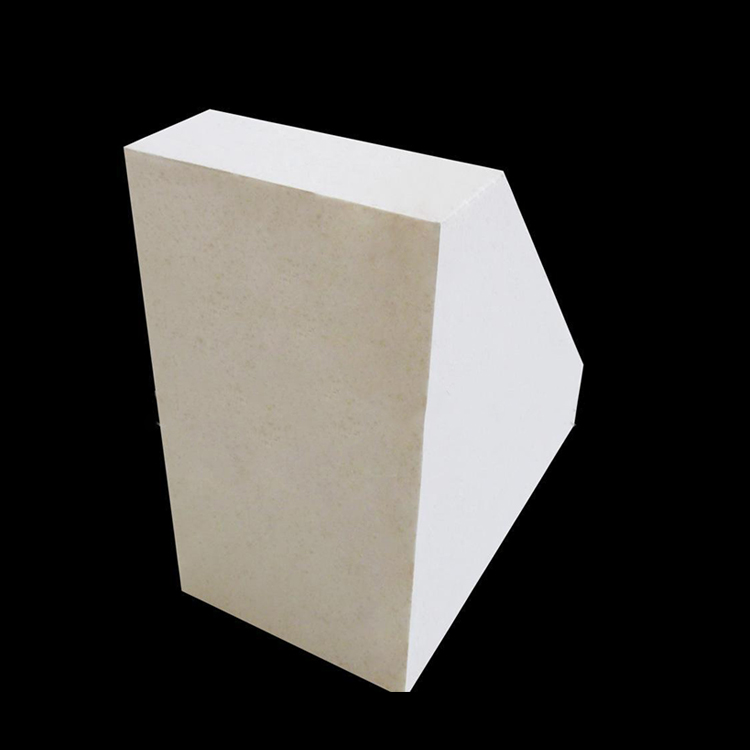

High-Performance Mullite Refractory Bricks: Enhancing Steel Furnace Efficiency Through Superior Thermal Shock and Creep Resistance

This article explores the exceptional performance of high-performance mullite refractory bricks in steel melting furnaces subjected to rapid temperature fluctuations. It highlights their outstanding thermal shock resistance and creep strength, supported by real-world case studies from integrated steel plants. Practical guidelines for material selection, installation best practices, and step-by-step maintenance techniques are provided—focusing on early detection of thermal cracks and creep deformation. Illustrated with charts and operational examples, this solution-oriented resource empowers engineers and maintenance teams to extend brick life, improve furnace stability, and maximize production efficiency. Designed for technical professionals seeking actionable insights, it aligns with industry advancements while ensuring safe, sustainable operations.

Why High-Performance Mullite Refractory Bricks Are Transforming Steel Melting Furnace Efficiency

In the high-stress environment of steel melting furnaces—where temperatures swing rapidly from 1,200°C to over 1,600°C—refractory materials must withstand extreme thermal shock and mechanical stress without failure. Among these, high-performance mullite bricks have emerged as a proven solution for extending furnace life, reducing downtime, and improving energy efficiency.

Recent field data from a major Chinese steel plant shows that switching to advanced mullite-based refractories reduced furnace lining replacement frequency by up to 35% within just 12 months. This translates directly into lower maintenance costs and higher production continuity—a critical advantage in today’s competitive market.

Key Performance Advantages in Real-World Conditions

- Exceptional Thermal Shock Resistance: Mullite bricks maintain structural integrity after repeated rapid heating and cooling cycles—critical during scrap charging or tapping operations.

- Low Creep at High Temperatures: At 1,500°C, standard bricks may deform significantly after 500 hours. Advanced mullite bricks show less than 0.5% creep under the same conditions (based on ASTM C133 test results).

- Improved Longevity: With proper installation and monitoring, mullite bricks can last 18–24 months versus 12–15 months with conventional options.

| Parameter |

Standard Brick |

Advanced Mullite Brick |

| Thermal Shock Resistance (cycles @ 1,500°C) |

~15 |

>40 |

| Creep at 1,500°C (after 500 hrs) |

~2.5% |

≤0.5% |

| Lining Life (avg.) |

12–15 months |

18–24 months |

Smart Selection & Installation Practices

Choosing the right mullite brick isn’t just about material composition—it’s about understanding your specific furnace operating profile. For instance, ladle furnaces require different grades than electric arc furnaces due to varying heat distribution patterns.

Proper installation is equally vital. A case study from a South Korean mill revealed that using improper mortar joints increased localized hot spots by 15%, accelerating wear. Our engineers recommend:

- Conducting pre-installation site inspections to assess existing lining condition.

- Using certified refractory mortar compatible with mullite bricks (e.g., low-alumina cement).

- Implementing a 7-day post-installation curing schedule before full operation.

Maintenance That Prevents Costly Failures

Regular visual inspection and thermographic scanning can detect early signs of damage such as micro-cracks or uneven wear. Engineers should check for:

- Surface spalling or flaking (indicates thermal fatigue).

- Deformation near hot zones (suggests creep accumulation).

- Unusual temperature gradients (may point to poor insulation or gas leaks).

A structured maintenance plan—including monthly thermal mapping and quarterly performance reviews—can extend service life by an additional 10–15%, according to our client network across Europe and Southeast Asia.