In the steel industry, the dry quenching system plays a pivotal role in enhancing energy efficiency and environmental performance. However, the refractory bricks used in this system are constantly exposed to extreme thermal conditions, and their thermal shock resistance directly determines the lining life and operational stability of the system. Let's delve into the key factors affecting the thermal shock resistance of high - alumina mullite refractory bricks in the dry quenching system.

Metallurgical engineers and plant managers often face challenges such as short lining life, frequent non - planned shutdowns, and high maintenance costs due to the poor thermal shock resistance of refractory bricks. These issues not only affect production efficiency but also increase the overall cost of the steel - making process.

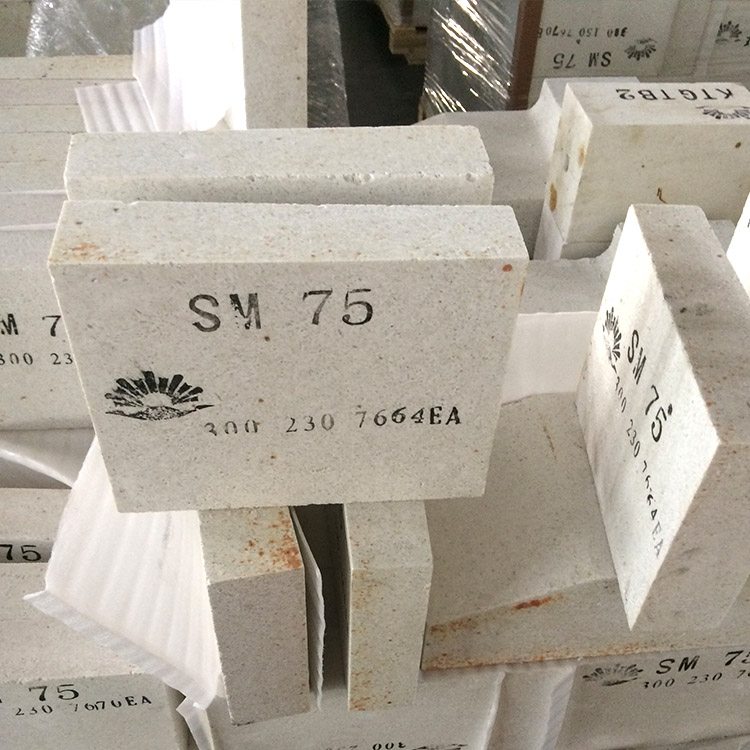

The ratio of mullite to corundum in high - alumina mullite refractory bricks is crucial. A proper ratio can significantly improve the thermal shock resistance. For example, in a certain dry quenching system, when the mullite/corundum ratio was adjusted from 3:2 to 4:1, the thermal shock cycle times increased from 30 to 50 times. This shows that the right raw material ratio can enhance the brick's ability to withstand thermal stress.

The pore distribution and grain boundary strength in the microstructure are key factors. An optimal pore distribution can effectively absorb thermal stress, while strong grain boundaries can prevent crack propagation. Through on - site observations, it was found that in bricks with a more uniform pore distribution, the spalling area after 50 thermal shock cycles was only 10%, compared to 25% in bricks with a non - uniform pore distribution.

The temperature gradient and holding time during the sintering process have a significant impact on the thermal shock resistance. By controlling the temperature gradient within 50°C per hour and extending the holding time from 2 hours to 3 hours, the thermal shock resistance of the bricks was improved. In actual cases, such process control reduced the risk of thermal shock failure by 30%.

The thermal cycle frequency in the service environment is an external factor that cannot be ignored. High - frequency thermal cycles can accelerate the thermal shock failure of refractory bricks. Through expert interviews, it was learned that in a high - frequency thermal cycle environment, the lining life of refractory bricks was reduced by nearly 40% compared to a low - frequency environment.

Based on the above analysis, here are some full - process optimization suggestions. In the raw material selection stage, ensure the proper mullite/corundum ratio. During the production process, strictly control the microstructure design and sintering process. In the installation and use stage, pay attention to the service environment and try to reduce the thermal cycle frequency. These measures can effectively improve the thermal shock resistance of refractory bricks, extend the lining life, and reduce non - planned shutdowns.

Are you still struggling with the poor thermal shock resistance of refractory bricks in your dry quenching system? Our high - quality mullite matrix combined with precision temperature - controlled technology can provide you with the best solution. Click here to learn more about our high - performance refractory bricks!