In the steel industry, the rapid temperature changes in steel furnaces present a significant challenge, often leading to thermal shock damage. This issue shortens the lining life of furnaces and increases maintenance frequency, which in turn raises operational costs and reduces production efficiency. In this article, we will explore how andalusite refractory bricks can effectively address these problems, offering a superior alternative to traditional high - alumina bricks.

Steel furnaces are subject to rapid temperature variations during normal operation. These rapid temperature changes create thermal stresses within the furnace lining. Traditional high - alumina bricks, commonly used in the past, often struggle to withstand these thermal shocks. As a result, the lining may crack, spall, or experience other forms of damage, leading to a shorter service life and more frequent maintenance.

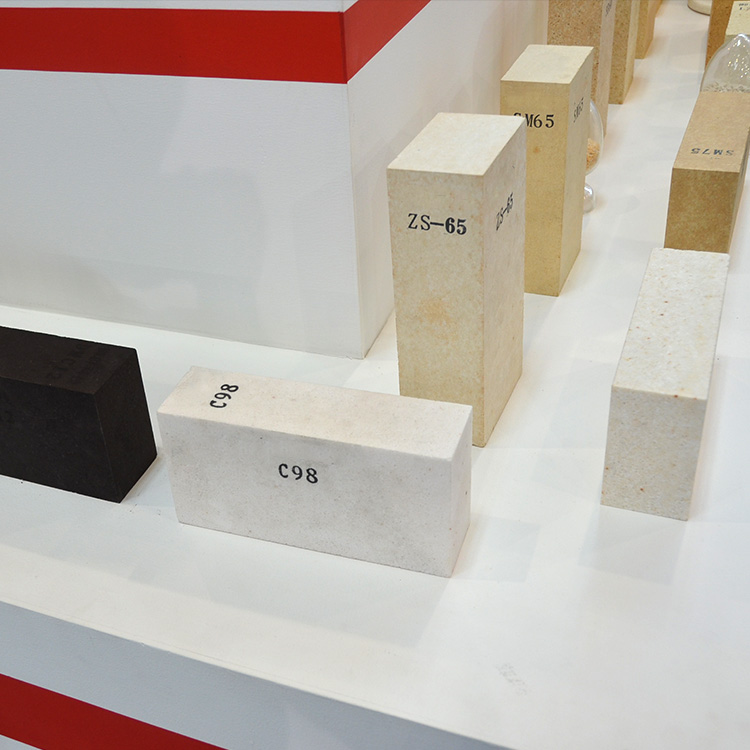

Let's take a look at the key performance indicators of high - alumina bricks and andalusite bricks. The following table shows the comparison in terms of thermal shock resistance, refractoriness under load, and creep resistance:

| Performance Indicator | High - Alumina Bricks | Andalusite Bricks |

|---|---|---|

| Thermal Shock Resistance (Number of cycles before failure) | 3 - 5 | 10 - 15 |

| Refractoriness under Load (°C) | 1450 - 1500 | 1550 - 1650 |

| Creep Resistance (Strain rate at high temperature) | 0.5 - 1% per 100 hours | 0.1 - 0.3% per 100 hours |

From the data in the table, it is clear that andalusite bricks outperform high - alumina bricks in these critical aspects. The higher number of thermal shock cycles before failure indicates that andalusite bricks can better withstand rapid temperature changes. The higher refractoriness under load means they can maintain their shape and strength under high - temperature and high - load conditions. And the lower creep resistance implies less deformation over time.

The unique crystal structure of andalusite is the key to its excellent thermal shock resistance and thermal stability. Imagine the crystal structure of andalusite as a well - built house with a flexible yet sturdy framework. When exposed to rapid temperature changes, this "framework" can expand and contract in a controlled manner, absorbing and dissipating the thermal stress. This is in contrast to the relatively rigid structure of high - alumina bricks, which are more likely to crack under thermal shock.

The andalusite crystal structure also allows for better heat transfer and distribution within the brick, reducing the temperature gradient and minimizing the risk of thermal stress concentration. This results in a more stable and durable refractory material.

To further illustrate the effectiveness of andalusite refractory bricks, let's look at some real - world application cases. A steel company in [Country] was facing frequent furnace lining failures due to thermal shock. After replacing the traditional high - alumina bricks with andalusite refractory bricks, the service life of the furnace lining increased by more than 30%. The maintenance frequency decreased significantly, from once every 3 months to once every 6 months. This not only reduced the maintenance cost but also increased the overall production efficiency of the steel plant.

"After switching to andalusite refractory bricks, we noticed a remarkable improvement in our furnace performance. The reduced maintenance frequency has allowed us to focus more on production, and the longer lining life has also saved us a significant amount of money." - A Steel Plant Engineer

In conclusion, andalusite refractory bricks offer a scientific and effective solution for steel furnaces facing thermal shock problems. By replacing traditional high - alumina bricks, steel companies can expect a significant increase in furnace lining life, a reduction in maintenance costs, and an improvement in overall production efficiency. This makes andalusite refractory bricks a smart choice for engineers and decision - makers in the steel industry.

If you are interested in learning more about the selection of refractory materials for steel furnaces, you can get the 'White Paper on the Selection of Refractory Materials for Steel Furnaces'.