In modern steel production, refractory bricks are critical components of high-temperature furnaces, ensuring structural integrity and energy efficiency. Rapid temperature fluctuations—known as rapid thermal cycling—pose significant challenges to these materials. This article examines the key performance indicators (KPIs) vital for refractory bricks under such demanding conditions, focusing on cold crushing strength, high-load softening temperature, creep resistance, and thermal shock resistance.

Understanding and quantifying these KPIs enables engineers to select optimal refractory materials tailored for steel mill furnaces experiencing swift heating and cooling cycles.

| Performance Indicator | Description | Typical Range / Benchmark |

|---|---|---|

| Cold Crushing Strength (CCS) | Resistance to mechanical stress at room temperature | ≥ 80 MPa for high-performance bricks |

| High Load Softening Temperature (HLST) | Temperature at which the brick deforms under load | > 1500 °C for steel furnace applications |

| Creep Resistance | Ability to resist slow deformation under mechanical stress at high temperatures | Creep strain rate ≤ 10⁻⁶ / hr at 1400 °C |

| Thermal Shock Resistance | Durability under rapid temperature changes | ≥ 30 cycles (ASTM C1326 standard) |

Each indicator measures a distinct aspect of the refractory brick's ability to withstand severe operational stress. For example, thermal shock resistance directly correlates with furnace uptime by minimizing brick cracking during cooling or heating events.

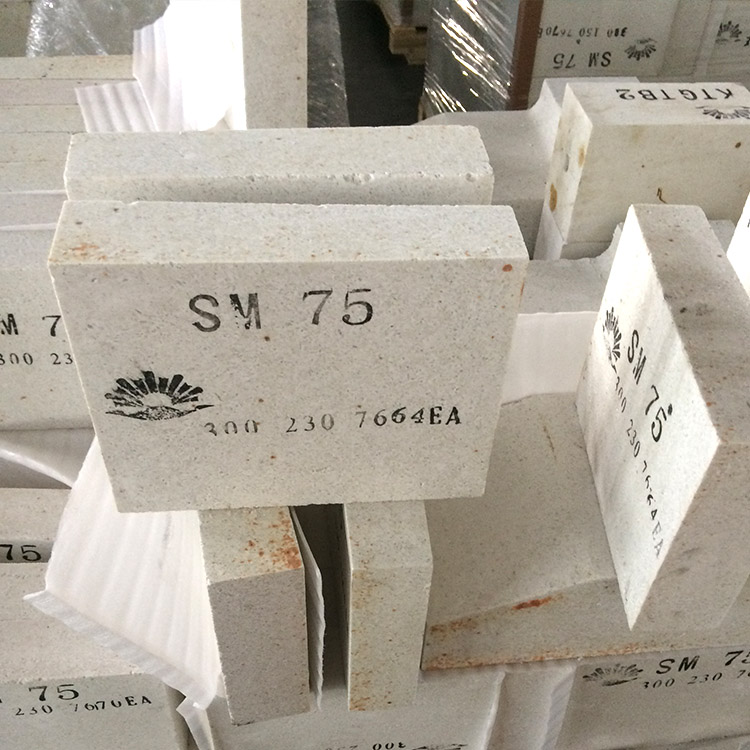

The selection of refractory bricks often comes down to balancing alumina content, silica phases like mullite, and the presence of zirconia or spinel inclusions. High alumina bricks (typically > 75% Al₂O₃) offer elevated softening points and excellent creep resistance but require precise control of pore structure to enhance thermal shock stability.

Microstructural advancements leveraging optimized firing schedules (typically 1600–1700 °C sintering temperature) and controlled grain growth have been shown to reduce microcracks and enhance intergranular bonding, thereby improving mechanical strength and thermal resilience. The incorporation of red spinel or red corundum phases is a common approach in high-performance bricks to enhance resistance to rapid temperature changes.

Case studies from integrated steel plants indicate that refractory bricks subjected to temperature shifts exceeding 100 °C per minute experience accelerated degradation. Poor thermal shock resistance can result in spalling, cracking, and ultimately premature failure—increasing unscheduled shutdowns.

Improved formulations of red corundum bricks have demonstrated 20-30% longer service life under these demanding conditions, potentially cutting downtime by up to 15%. This directly translates to lower maintenance costs and more stable furnace operations.

Implementing rigorous selection criteria and working closely with refractory suppliers ensures the chosen products align with the steel plant’s operational demands and economic goals.

Discover More About Thermal Shock Resistance Testing Standards