In the high - temperature environment of steel furnaces, the performance of refractory materials is crucial for the efficient and safe operation of the furnace. Andalusite refractory bricks have emerged as a popular choice due to their excellent creep - resistance properties, especially under rapid temperature change conditions.

The creep - resistance mechanism of andalusite refractory bricks in steel furnaces with rapid temperature changes lies in their unique crystal structure. Andalusite has a stable crystal lattice that can effectively resist deformation under high - temperature stress. Empirical data shows that in a steel furnace with a temperature range of 1300 - 1600°C and rapid temperature changes of up to 200°C per hour, andalusite refractory bricks can maintain a creep rate of less than 0.5% over 1000 hours of continuous operation. This is significantly lower compared to traditional high - alumina bricks, which may have a creep rate of 1 - 2% under the same conditions.

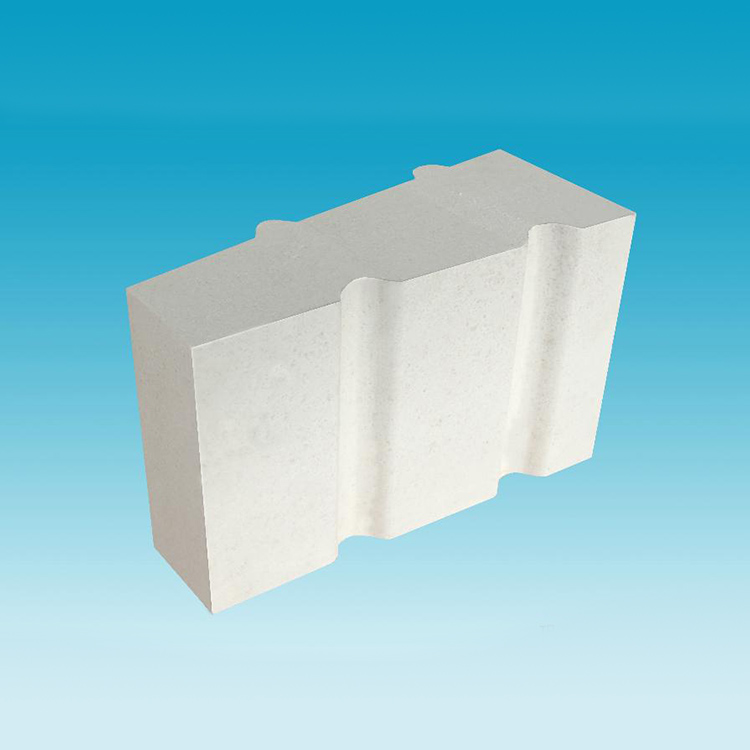

When selecting andalusite refractory bricks for steel furnaces, several factors need to be considered. The alumina content should be between 55 - 65% to ensure good high - temperature performance. The bulk density should be around 2.3 - 2.5 g/cm³, which is related to the strength and thermal conductivity of the bricks.

During the installation process, it is important to follow strict procedures. The bricks should be laid evenly with a joint width of no more than 2mm to prevent heat leakage. Common installation mistakes include improper alignment and uneven mortar application, which can lead to premature failure of the refractory lining. By avoiding these mistakes, the service life of the refractory bricks can be extended by up to 30%.

Typical failures in andalusite refractory bricks in steel furnaces include thermal shock cracks and structural deformation. To establish a preventive maintenance system, regular inspections should be carried out. For example, visual inspections can be done every 100 hours of operation, and non - destructive testing such as ultrasonic testing can be performed every 500 hours. By detecting early signs of damage, timely repairs can be made, reducing the risk of major breakdowns.

"In our steel plant, after switching to andalusite refractory bricks, we have seen a significant reduction in maintenance costs and an increase in furnace uptime. The excellent creep - resistance of these bricks has truly made a difference." - A customer from a large - scale steel manufacturing company

Let's take a look at an industry case. A steel mill replaced its traditional high - alumina bricks with andalusite refractory bricks in a medium - sized steel furnace. The results showed that the service life of the refractory lining increased from 12 months to 18 months. Additionally, the energy consumption of the furnace decreased by 10% due to the better insulation properties of andalusite bricks.

The use of andalusite refractory bricks in steel furnaces brings significant economic and safety benefits. The extended service life reduces the frequency of refractory lining replacement, saving on material and labor costs. The lower energy consumption also contributes to cost savings. From a safety perspective, the excellent creep - resistance and thermal shock stability of andalusite bricks reduce the risk of furnace lining collapse, ensuring the safety of the production process.

In conclusion, andalusite refractory bricks offer a high - performance solution for steel furnaces. Their excellent creep - resistance, combined with proper selection, installation, and maintenance, can greatly enhance the efficiency, safety, and cost - effectiveness of steel furnace operations. 立即获取完整技术手册与定制化选型建议