Have you ever wondered why your dry quenching system’s high-alumina and mullite refractory bricks crack the moment they cool? The root cause is often thermal shock damage—where extreme temperature gradients induce microfractures that propagate rapidly under service conditions. To help you avoid costly failures, this tutorial guides you through scientifically proven methods to evaluate thermal shock resistance, combining rigorous laboratory protocols with real-world field data.

Traditionally, many engineers rely solely on the load softening temperature as the key metric for refractory brick selection. While this parameter indicates the temperature at which bricks soften under mechanical load, it fails to capture the dynamic stresses induced by rapid thermal cycling—a reality in dry quenching furnaces where temperature differentials (ΔT) can exceed 850°C within seconds.

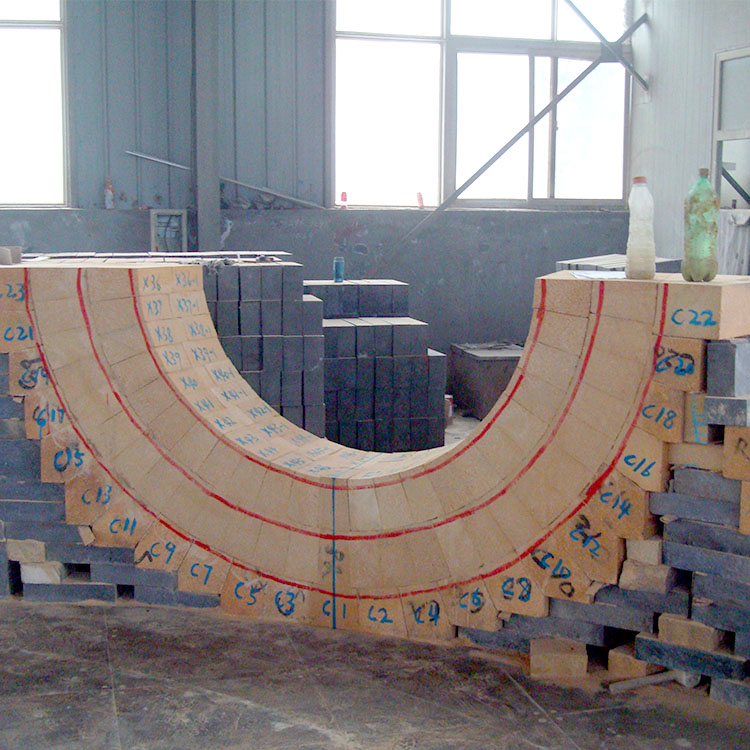

Instead, a comprehensive approach that evaluates bricks using standardized water quench tests (ΔT = 850°C) provides a quantitative measure of thermal shock resistance. This involves heating refractory samples to high temperatures and suddenly cooling them in water, simulating critical cooling scenarios. Such tests reveal latent vulnerabilities invisible to static load assessments.

While laboratory water quench data sets a solid benchmark, the true test lies in correlating these results with onsite crack propagation rates. Tracking crack extension under real temperature cycles offers invaluable feedback on refractory durability and identifies bricks with optimal thermal shock resistance.

Case studies reveal that bricks passing the stringent ΔT=850°C water quench test typically show 30-40% slower crack propagation rates during plant operation compared to bricks qualified only by load softening temperature. This measurable difference translates into extended furnace uptime and reduced maintenance interventions.

Infrared thermography (IRT) emerges as a cutting-edge tool to proactively identify early-stage thermal shock damage before macroscopic cracks appear. By detecting localized heat anomalies and abnormal temperature gradients during routine inspections, you can pinpoint zones undergoing excessive thermal stress.

For example, experienced on-site engineers have leveraged infrared cameras to spot “hot spots” and non-uniform cooling patches on refractory surfaces that directly correlate with microstructural damage. This novel approach facilitates targeted interventions, shifting your maintenance strategy from reactive repairs to proactive prevention.

Transitioning from a reactive maintenance model—where action is taken only after damage becomes evident—to a proactive approach powered by infrared thermography helps you extend refractory service life, minimize unscheduled downtime, and optimize operating costs.

Adoption of early detection techniques empowers plant managers and engineers to schedule timely repairs, adjust operating parameters, and choose refractory brands with confidence based on verified thermal shock performance.