In high - temperature industries such as steel and cement production, the stability of Al₂O₃ content in refractory clay bricks is of paramount importance. Al₂O₃ is a key component that significantly influences the refractory performance of these bricks. Scientifically, a stable Al₂O₃ content ensures consistent physical and chemical properties of the refractory clay bricks. For example, according to international refractory material standards, a refractory clay brick with an Al₂O₃ content stability within ±1% can maintain its high - temperature resistance at up to 1700°C. This stability directly affects the safety of furnace linings. When the Al₂O₃ content fluctuates, it may lead to uneven expansion and contraction of the bricks under high - temperature conditions, increasing the risk of cracks and damage to the furnace lining.

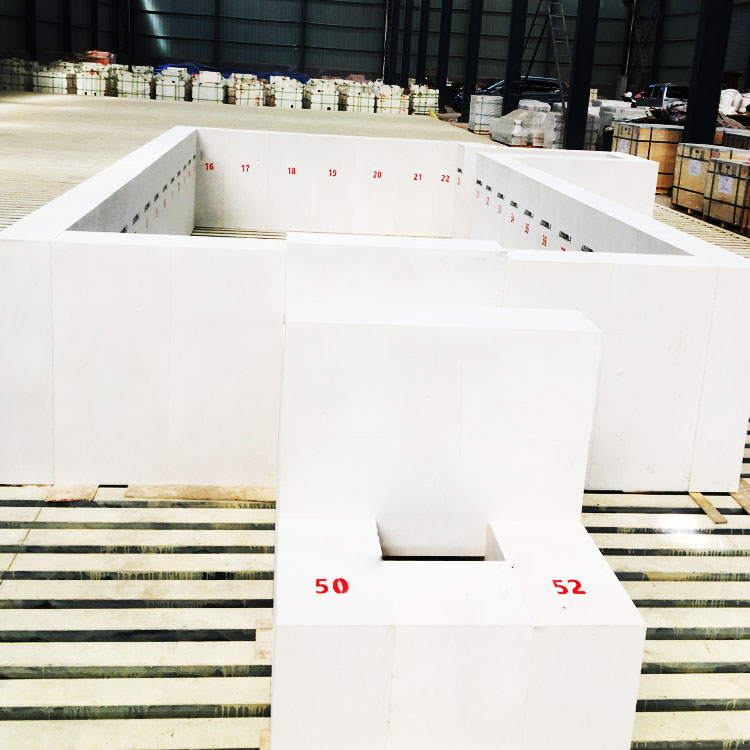

These high - alumina dense wear - resistant clay bricks can withstand extremely high temperatures. In steelmaking processes, where the temperature in the furnace can reach over 1600°C, these bricks can maintain their structural integrity. The high - temperature resistance is mainly due to the stable Al₂O₃ content and the unique crystal structure of the bricks. They can prevent the penetration of molten metal and slag, protecting the furnace lining from damage.

In high - temperature industrial environments, the inner lining of the furnace is subject to continuous abrasion from the flow of molten materials. The high - alumina dense wear - resistant clay bricks have excellent wear - resistant properties. Tests show that compared with ordinary refractory bricks, their wear rate is reduced by up to 30% under the same working conditions. This not only extends the service life of the furnace lining but also reduces the frequency of maintenance and replacement.

The weak acid characteristic of these bricks is another significant advantage. In the chemical reactions that occur in high - temperature furnaces, the weak acid nature of the bricks can reduce the intensity of chemical reactions with the surrounding substances. For example, in cement production, where there are various acidic and alkaline substances in the kiln, the weak acid compatibility of the bricks can prevent excessive corrosion and chemical erosion, thereby extending the service life of the furnace lining.

These refractory clay bricks strictly comply with international quality standards such as ISO 9001. This ensures that the products have high - quality and reliable performance. The compliance with standards also provides a guarantee for international trade and the use of these products in different countries and regions.

In the steel industry, the use of high - alumina dense wear - resistant clay bricks can significantly improve the operational efficiency of the furnace. By protecting the furnace lining, it reduces the downtime caused by furnace lining repairs. For example, a steel plant in Europe reported that after using these refractory clay bricks, the annual furnace shutdown time for lining maintenance was reduced from 30 days to 15 days, increasing the annual steel production by about 5%. At the same time, the stable performance of the bricks also reduces the risk of furnace accidents, ensuring the safety of production.

In the cement industry, the high - temperature environment in the kiln requires high - performance refractory materials. The high - alumina dense wear - resistant clay bricks can resist the corrosion of cement clinker and the high - temperature airflow. A cement factory in Asia found that by using these bricks, the service life of the kiln lining was extended from 1 year to 1.5 years, reducing the cost of lining replacement and maintenance. It also improved the stability of the cement production process, increasing the output quality and quantity.

For procurement and technical decision - makers, when evaluating refractory materials, they should focus on several key indicators. Firstly, the Al₂O₃ content and its stability are crucial. As mentioned above, a stable Al₂O₃ content within a certain range can ensure the performance of the bricks. Secondly, the high - temperature resistance and wear - resistant performance should be considered. The ability to withstand high temperatures and resist wear directly affects the service life of the furnace lining. Thirdly, the chemical compatibility, especially the weak acid compatibility, is also an important factor. To control risks, it is recommended to choose products from reliable suppliers with a good reputation and strict quality control systems. Regular inspections and maintenance of the furnace lining can also help detect and solve potential problems in time.

Are you looking for high - performance refractory clay bricks to optimize your high - temperature industrial production? Click here to learn more about our Al₂O₃ stable content refractory clay bricks and how they can benefit your business.