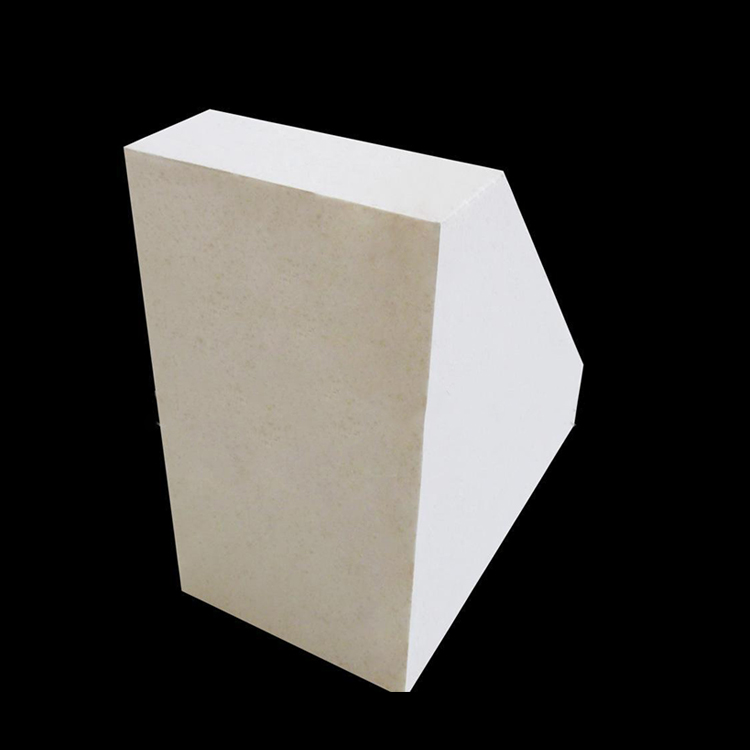

In the steel industry, high-temperature melting furnaces are subjected to frequent temperature changes. Traditional high-alumina bricks often fall short due to their inadequate thermal shock resistance, leading to a shortened furnace lining lifespan and an increased risk of furnace shutdowns. This article delves into the core properties of andalusite refractory bricks, including cold strength, refractoriness under load, creep resistance, and thermal shock resistance, and reveals how scientific material selection and manufacturing processes enable them to serve stably.

Before we explore the application of andalusite refractory bricks, it's essential to understand the basic properties of refractory materials. Cold strength refers to the ability of the brick to withstand pressure at room temperature. Refractoriness under load measures the temperature at which the brick begins to deform under a specified load. Creep resistance is the ability to resist deformation over time under a constant load and high temperature, and thermal shock resistance is the ability to withstand rapid temperature changes without cracking or spalling.

In typical steel - making equipment such as converters and electric furnaces, the performance differences between andalusite bricks and high - alumina bricks are significant. High - alumina bricks, although widely used, tend to crack and spall under rapid temperature changes due to their relatively poor thermal shock resistance. In contrast, andalusite bricks have a unique crystal structure that allows them to expand and contract more uniformly during temperature changes, reducing the risk of cracking.

| Properties | High - Alumina Bricks | Andalusite Bricks |

|---|---|---|

| Cold Strength | Moderate | High |

| Thermal Shock Resistance | Poor | Excellent |

| Refractoriness under Load | Good | Very Good |

| Creep Resistance | Average | High |

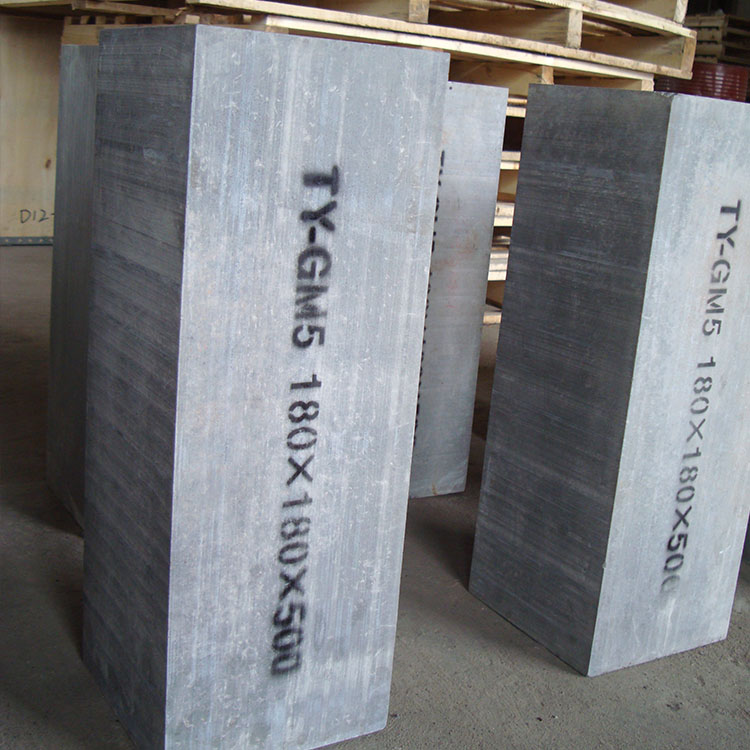

The performance of andalusite bricks is also closely related to their manufacturing processes. Raw material配比 plays a crucial role. The right combination of andalusite and other additives can enhance the overall performance of the bricks. The firing system, including firing temperature and time, also affects the crystal structure and density of the bricks, thereby influencing their properties.

In an anonymous steel mill, after replacing traditional high - alumina bricks with high - performance andalusite bricks, the furnace lining lifespan increased by 40%. This significant improvement not only reduced the frequency of furnace shutdowns but also extended the maintenance cycle. Moreover, due to the better insulation properties of andalusite bricks, energy efficiency was improved, resulting in cost savings.

When selecting refractory bricks for high - temperature melting furnaces, consider the specific operating conditions of your equipment. If your furnace experiences rapid temperature changes, andalusite bricks are an ideal choice. Look for products with high cold strength, excellent thermal shock resistance, and high refractoriness under load. Also, pay attention to the reputation of the manufacturer and their quality control processes.

In conclusion, andalusite refractory bricks offer a reliable solution for extending the service life of high - temperature melting furnace linings in the steel industry. By reducing the frequency of furnace shutdowns, extending maintenance cycles, and improving energy efficiency, they can help your business achieve cost - reduction and efficiency - improvement goals. Click here to learn more about our high - quality andalusite refractory bricks and take the first step towards optimizing your furnace operations.