In the dry quenching system of steel plants, refractory bricks are prone to failure phenomena such as spalling and cracking due to frequent thermal shocks. This directly affects the continuity of production and the service life of equipment. An engineer on - site once witnessed a steel plant's non - planned shutdown because the refractory bricks in the dry quenching system couldn't withstand the thermal shocks. Such incidents not only increase the operating costs but also pose potential safety risks.

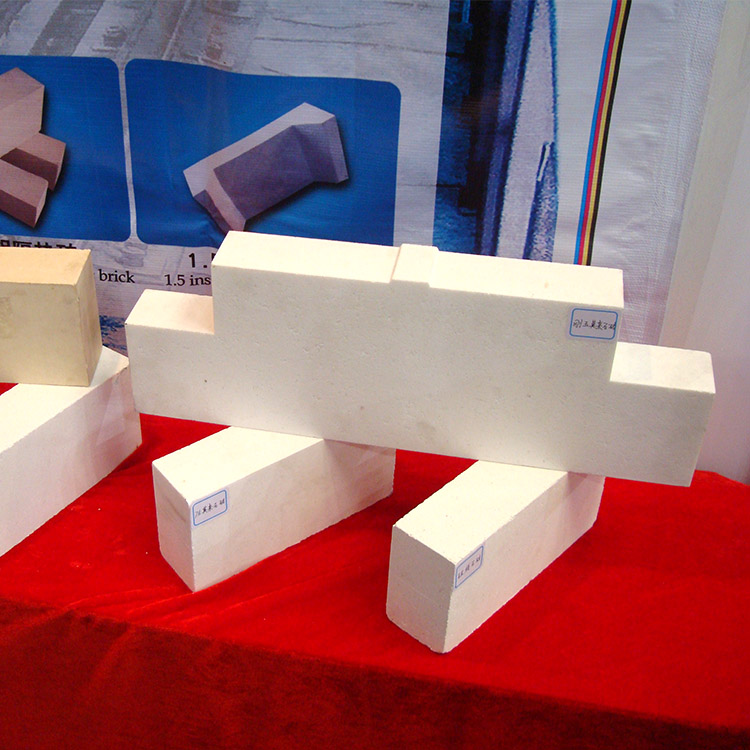

The thermal shock resistance of high - alumina mullite refractory bricks is determined by several core factors. First, the raw material ratio is crucial. For example, the ratio of mullite to corundum significantly impacts the performance. A proper ratio can enhance the overall stability of the refractory bricks. Second, the microstructure, including the pore distribution and grain boundary strength, plays an important role. A well - designed pore structure can effectively absorb thermal stress, while strong grain boundaries can prevent crack propagation.

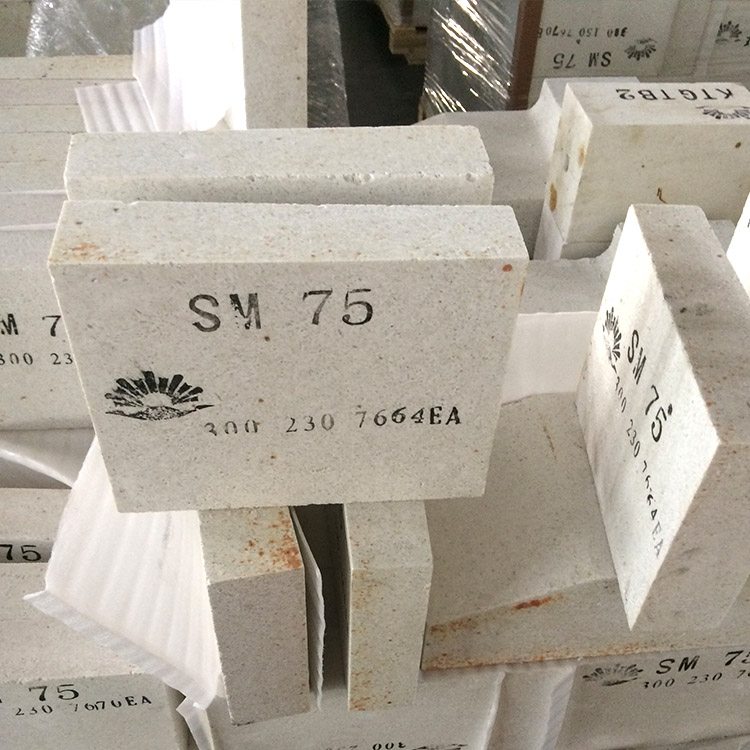

The sintering process control, such as the heating rate and holding time, also affects the thermal shock resistance. A slow heating rate from 900°C to 1150°C and an appropriate holding time can ensure a more uniform internal structure of the bricks. Finally, the service environment, especially the frequency of thermal cycles, has a direct influence. In a high - frequency thermal cycle environment, the refractory bricks are more likely to experience failure.

To better understand the impact of different factors, real - world data from thermal shock tests are used for comparison. For instance, different formulations of high - alumina mullite refractory bricks were tested under the same thermal cycle conditions. The results showed that bricks with an optimized raw material ratio and microstructure could withstand more thermal cycles. One formulation could endure 150 thermal cycles with only a 10% spalling area, while another less - optimized formulation failed after only 80 cycles with a 30% spalling area.

To improve the thermal shock resistance of high - alumina mullite refractory bricks, a comprehensive approach from procurement to installation is necessary. When selecting raw materials, choose high - quality ones with appropriate ratios. During the manufacturing process, strictly control the sintering parameters. At the installation stage, ensure proper installation techniques to reduce potential stress points. By implementing these strategies, the risk of non - planned furnace shutdowns can be significantly reduced, and the service life of the furnace lining can be extended by more than 30%.

We encourage you to share your experiences. What kind of thermal shock failure modes have you encountered in your work? Leave a comment below to share your insights and learn from others. If you want to learn more about improving the thermal shock resistance of high - alumina mullite refractory bricks and get a comprehensive solution for your refractory material needs, click here.

You've learned about the importance of thermal shock resistance and the factors affecting it. Now, it's your turn to take action. Share your experiences and let's work together to improve the performance of refractory materials in the metallurgical industry. You encountered which thermal shock failure mode? Welcome to leave a message and communicate!