In the coke dry quenching (CDQ) system, refractory bricks are prone to failure problems such as spalling and cracking due to frequent thermal shocks. These issues seriously affect the service life of the kiln and production safety. This article delves into the four key factors influencing the thermal shock resistance of high - alumina mullite refractory bricks: raw material ratio, microstructure design, sintering process control, and the thermal cycle frequency of the service environment.

The ratio of mullite to corundum in the raw materials plays a crucial role. A higher proportion of mullite can enhance the thermal shock resistance to a certain extent. For example, in some experiments, when the mullite content increased from 40% to 60%, the spalling area after 100 thermal shock cycles decreased from about 20% to 12%. Different raw material ratios lead to different physical and chemical properties of the refractory bricks, which directly affect their performance in the CDQ system.

The microstructure of refractory bricks, including pore distribution and grain boundary strength, has a significant impact on thermal shock resistance. A well - distributed pore structure can effectively absorb thermal stress. Engineers have found that when the pore size is uniformly distributed between 1 - 3 mm, the thermal shock resistance is relatively better. In terms of grain boundary strength, a stronger grain boundary can resist the propagation of cracks. In actual service, bricks with better - controlled microstructures have shown 30% less damage after 3 years of service compared to those with poor microstructures.

Manufacturing process parameters such as heating rate and holding time are also critical. A slow heating rate can ensure uniform internal temperature changes of the bricks during the sintering process, reducing internal stress. For example, when the heating rate is controlled at 2 - 3°C per minute, the quality of the sintered bricks is more stable. A proper holding time can promote the full reaction of the raw materials, improving the density and strength of the bricks. In contrast, improper process parameters can lead to defects in the bricks, reducing their thermal shock resistance.

Temperature fluctuation frequency and cooling methods in the on - site environment directly affect the thermal shock endured by the refractory bricks. A high - frequency temperature fluctuation can cause severe thermal stress fatigue on the bricks. For instance, in a system with a temperature fluctuation frequency of more than 5 times per day, the service life of the bricks is significantly reduced. Different cooling methods, such as air cooling and water cooling, also have different effects on the bricks. Water cooling is more likely to cause rapid temperature changes, increasing the risk of cracking.

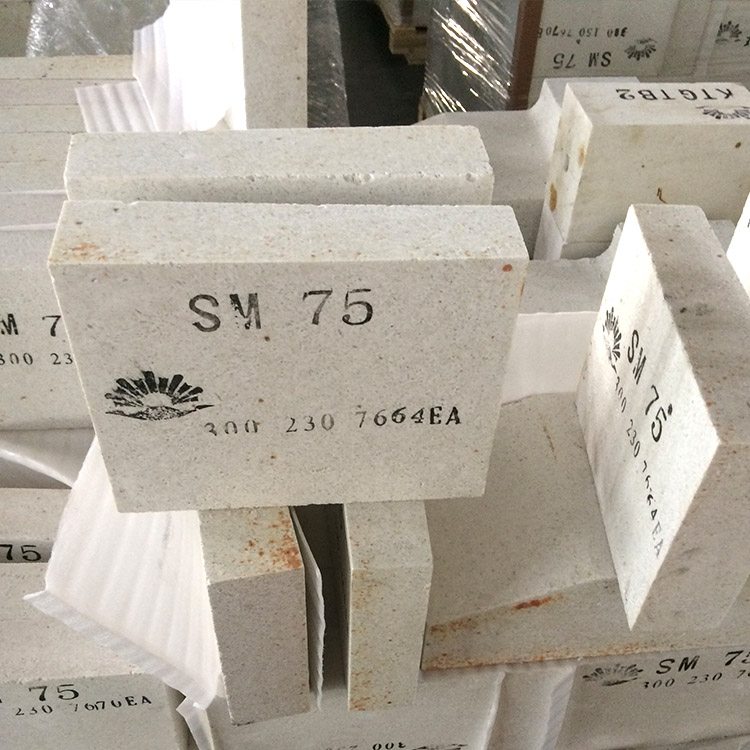

To enhance the thermal shock resistance of refractory bricks in the CDQ system, real - world case data has been used to compare the performance of different formulations. Through these comparisons, we can clearly see the differences in the performance of refractory bricks under different conditions, which helps metallurgical engineers accurately identify risk points.

Many front - line engineers have also shared their insights in practice. They emphasized the importance of comprehensive consideration of various factors from material selection to installation. For example, when selecting materials, engineers need to consider the specific operating conditions of the CDQ system, such as temperature range and thermal shock frequency. During the installation process, ensuring proper installation techniques can also improve the overall performance of the refractory lining.

Based on the above analysis, the following selection and installation suggestions are provided. When selecting refractory bricks, choose products with a reasonable mullite - corundum ratio, a well - distributed pore structure, and a strong grain boundary. In terms of installation, ensure that the installation process is in strict accordance with the specifications, and pay attention to the expansion joints to avoid stress concentration. By following these suggestions, the service life of the lining can be extended by more than 30%, and the risk of unplanned furnace shutdowns can be significantly reduced.

Do you have any experiences with thermal shock failure modes? We welcome you to leave a message and share. If you want to learn more about how to optimize the thermal shock resistance of refractory bricks in your CDQ system, click here for more in - depth information and solutions.