Thermal shock degradation of refractory bricks in dry quenching systems poses a significant threat to steelworks operations, leading to frequent unplanned shutdowns and elevated maintenance costs. High-alumina mullite refractory bricks are pivotal in maintaining furnace lining integrity, yet their performance under repeated thermal cycling depends on multiple technical factors. This article meticulously dissects the key determinants impacting thermal shock resistance — raw material proportions, microstructural design, sintering processes, and operational conditions—empowered by empirical data to enable metallurgical engineers optimize the entire refractory lifecycle for enhanced furnace lining longevity.

In steel manufacturing, refractory bricks exposed to high-temperature environments experience rapid cooling and heating cycles, triggering crack initiation, spalling, and eventual structural failure. Such deterioration leads to compromised furnace linings, risking operational safety and costly production downtime. For instance, a typical steel plant facing repeated thermal shock damage may incur downtime exceeding 120 hours annually, equating to losses surpassing $500,000 USD. Understanding and mitigating these failure modes through material science and process optimization is imperative for sustained productivity and risk management.

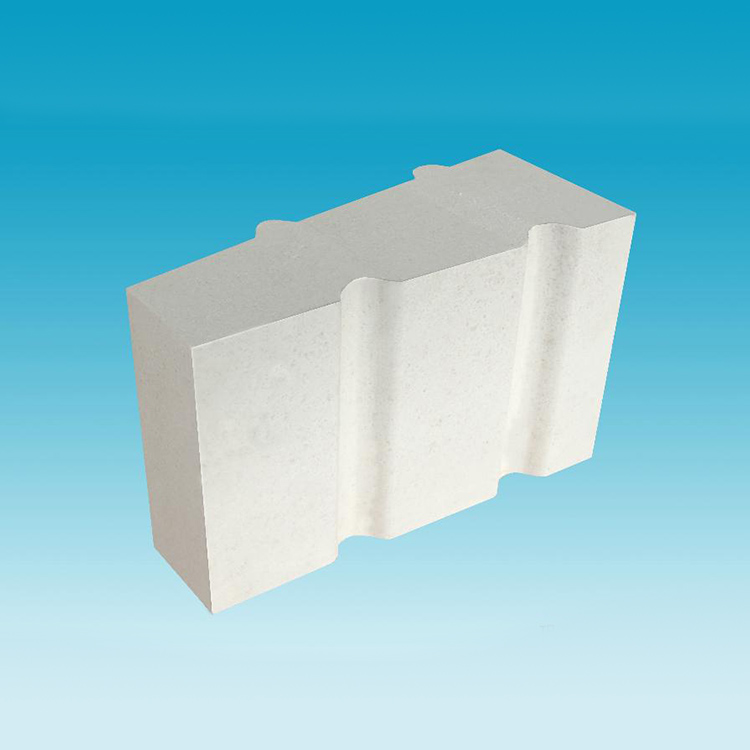

The mullite (3Al2O3·2SiO2) to corundum (Al2O3) ratio profoundly impacts the refractory's thermal shock resistance. An optimal balance typically falls within 75-85% mullite and 15-25% corundum. Mullite provides robust structural stability and crack deflection, while corundum enhances hardness and thermal conductivity. Deviations from this range can induce micro-cracking due to mismatched thermal expansion coefficients.

Porosity plays a dual role: controlled micro-porosity (~8-12%) acts as thermal stress cushions, mitigating crack propagation, whereas excessive porosity (>15%) diminishes mechanical strength. Uniform gas pore distribution avoids localized stress concentrations. Meanwhile, strengthening grain boundaries, especially at the mullite-corundum interfaces, enhances cohesion and reduces susceptibility to intergranular fracture during thermal cycling.

Precise sintering schedules critically dictate phase development and densification. An ideal regime features a moderate temperature ramp rate of 5-8°C/min to avoid thermal gradients, combined with a soaking time of 4-6 hours at 1600°C to ensure optimal grain growth and pore elimination. Inconsistent procedures introduce residual stresses and incomplete bonding, leading to premature thermal shock damage.

The operational environment’s thermal cycling frequency directly correlates with refractory brick endurance. High cycle counts (>1000 cycles/year) exponentially escalate microstructural fatigue. Additionally, fluctuating thermal loads and mechanical abrasion from coke particles worsen degradation rates. Tailoring materials to anticipated service stresses can extend furnace lining lifespan by up to 30%.

Data collected from three steel plants employing varied high-alumina refractory formulas revealed stark contrasts in thermal shock resilience. Formula A, with 80% mullite, optimized porosity (~10%), and rigorously controlled sintering, sustained 1200 thermal shock cycles with less than 5% surface spalling. In contrast, Formula B, lacking precise microstructural control and utilizing a faster sintering ramp, failed after just 600 cycles, with spalling exceeding 15%. This correlation underscores the tangible benefits of meticulous material engineering aligned with process parameters.

How have your steel operations tackled the challenge of refractory thermal shock? Which microstructural or process innovations have yielded the most significant improvements in furnace lining durability? Your practical insights can foster industry-wide advancements. Engage with our expert panel below.