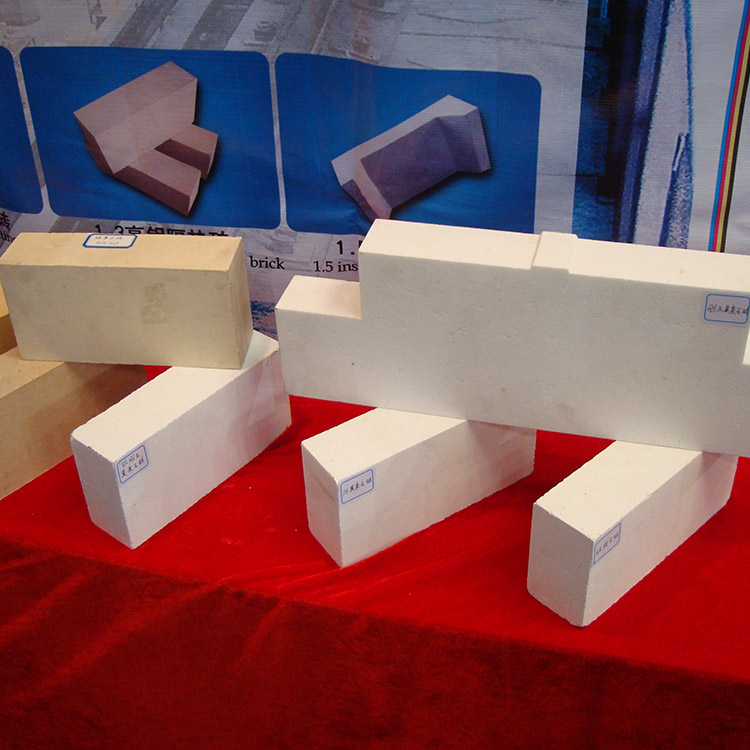

High-alumina mullite refractory bricks are critical components in dry quenching systems used in metallurgical industries, tasked with enduring extreme thermal cycles and preventing costly downtimes. The challenge of thermal shock-induced failure in these materials often leads to operational inefficiencies and maintenance headaches.

Dry quenching furnaces expose refractory bricks to abrupt temperature variations exceeding 800°C within seconds, creating severe thermal gradients. These rapid temperature shifts induce stresses that may cause cracking, spalling, or total material failure.

Laboratory-based thermal shock tests, such as the ΔT=850°C water quenching method, simulate these extreme conditions. However, relying solely on lab data risks misinterpreting field performance due to different cooling rates, load conditions, or installation variations.

A combined assessment approach integrates lab thermal shock cycles with on-site inspection data—particularly crack density and spalling depth measurements collected after real service periods. For example, recent case studies demonstrate that bricks retaining less than 10% crack propagation area after 500 thermal cycles correspond to longer operational lifetimes exceeding 12 months.

Importantly, field data sometimes reveal discrepancies, where bricks passing standard tests prematurely fail under operational stresses. This highlights common pitfalls such as:

Modern dry quenching operations increasingly adopt infrared (IR) thermal imaging to monitor in situ refractory conditions. IR cameras identify early-stage cracking and hotspot formation non-destructively, enabling predictive maintenance before visible damage occurs.

Engineering teams report that combining traditional visual inspections with IR thermography reduces unplanned outages by 30% and maintenance costs by up to 25%. This technology supports transition from reactive repairs to proactive asset management.

A steel plant deploying high-quality mullite bricks experienced significantly improved refractory longevity. After rigorous lab thermal shock testing showed 85% strength retention post 500 cycles, on-site inspections confirmed only minor superficial cracking with no spalling after 11 months of continuous operation.

These results contrasted with previous materials that, despite adequate lab performance, failed after 6 months due to unconsidered operational variables. Enhanced selection criteria based on holistic data analytics, including thermal imaging and microstructural testing, ensured optimized brick procurement for targeted dry quenching conditions.

For metallurgical and refractory materials professionals, recognizing the nuanced interplay of lab tests and field realities is essential:

Unlock the full potential of your dry quenching system by embracing scientifically validated refractory materials and advanced monitoring protocols.

Download Our Exclusive Technical Whitepaper on High-Alumina Mullite Refractory Bricks & Thermal Shock Performance