In the realm of refractory materials, several core performance indicators play a pivotal role in determining their suitability for specific applications. Let's start by defining and understanding the testing methods of three crucial indicators: load - softening temperature, thermal shock resistance, and creep resistance.

Load - softening temperature refers to the temperature at which a refractory material begins to deform under a specified load. This can be measured using a high - temperature testing furnace where a sample is subjected to a constant load while the temperature is gradually increased until a certain deformation occurs. Thermal shock resistance is the ability of a refractory material to withstand sudden changes in temperature without cracking or spalling. It is usually tested by rapidly heating and cooling the sample multiple times and observing its structural integrity. Creep resistance is the material's ability to resist deformation under a constant load over an extended period at high temperatures, which can be evaluated through long - term high - temperature creep tests.

In the steel industry, typical working conditions such as those in electric furnaces and heating furnaces have specific requirements for refractory materials. The load - softening temperature directly affects the stability of the furnace lining under high - temperature and high - load conditions. If the load - softening temperature of the refractory material is too low, the furnace lining may deform during operation, leading to potential safety hazards and a shortened service life.

Thermal shock resistance is crucial for furnaces that experience frequent temperature changes. In an electric furnace or a heating furnace that starts and stops frequently, the refractory material is exposed to rapid temperature fluctuations. Poor thermal shock resistance can cause the material to crack and spall, reducing the overall integrity of the furnace lining. Creep resistance also plays an important role, especially in long - term continuous operation. A refractory material with low creep resistance may gradually deform over time, which can lead to changes in the furnace's internal structure and affect its performance.

| Performance Indicator | Impact on Furnace Lining Life |

|---|---|

| Load - Softening Temperature | Low value leads to deformation under high - temperature and high - load, shortening service life |

| Thermal Shock Resistance | Poor resistance causes cracking and spalling in rapid temperature changes, reducing integrity |

| Creep Resistance | Low resistance results in gradual deformation during long - term operation, affecting furnace performance |

High - alumina bricks are a commonly used refractory material in the steel industry. However, they have significant drawbacks when used in heating furnaces with frequent start - stop cycles. At the root of the problem is their relatively poor performance in terms of thermal shock resistance and creep resistance under rapid temperature changes.

When exposed to rapid temperature changes, high - alumina bricks are prone to cracking due to the large thermal stress generated within the material. The internal structure of high - alumina bricks is not well - adapted to sudden temperature fluctuations, which causes the material to expand and contract unevenly. This uneven expansion and contraction lead to the formation of cracks and eventually spalling. In addition, the creep resistance of high - alumina bricks may also be insufficient under long - term high - temperature operation, resulting in gradual deformation of the furnace lining.

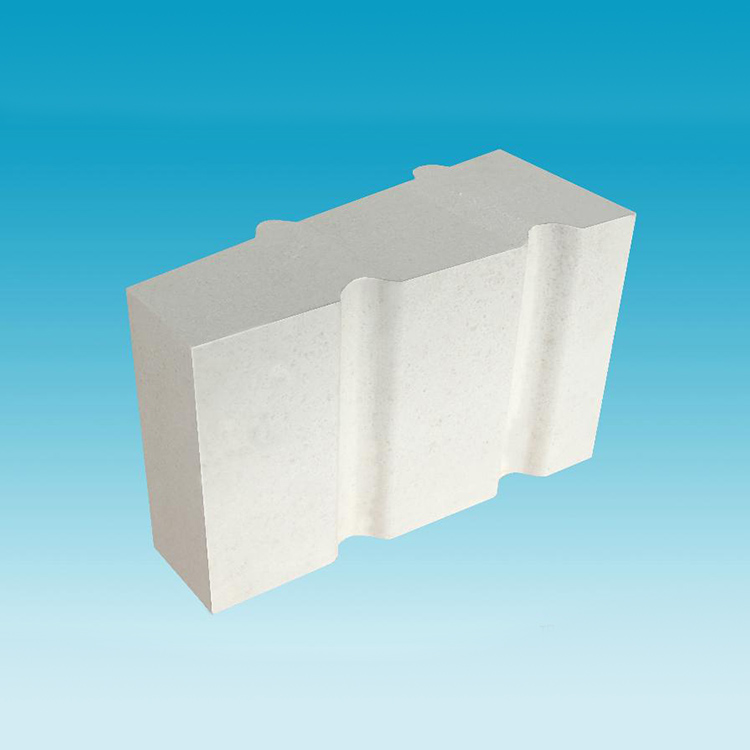

In contrast to high - alumina bricks, kyanite refractory bricks show excellent performance in rapid temperature change conditions. Through the optimization of their microstructure and manufacturing process, kyanite refractory bricks have a more stable internal structure. Their unique crystal structure allows them to better adapt to temperature changes, resulting in superior thermal shock resistance.

In a real - world steel mill case, a steel plant replaced the high - alumina bricks in their heating furnace with kyanite refractory bricks. After a period of operation, it was found that the frequency of cracking and spalling of the furnace lining was significantly reduced. The service life of the furnace lining was extended by approximately 30%, and the number of furnace shutdowns due to refractory material failure was also greatly decreased. This not only reduced the maintenance cost but also improved the overall production efficiency of the steel plant.

Rational material selection in the steel industry can bring multiple benefits. By choosing the right refractory material, steel enterprises can significantly reduce operating costs. The extended service life of the furnace lining means less frequent replacement of refractory materials, which directly reduces material procurement costs. Moreover, the reduction in furnace shutdowns due to refractory material failure also saves on the cost associated with production interruptions.

In addition, a longer - lasting furnace lining can improve energy efficiency. A well - functioning furnace lining can better retain heat, reducing heat loss and thus saving energy. It also allows for a more stable and efficient operation of the furnace, which is crucial for the quality and quantity of steel production.

To learn more about the standards for thermal shock resistance testing of refractory materials, click here.